1. Buff or roughen the tube surface to be patched

for at least 1 inch around the hole. Then clean it with

solvent. When a buffer is not available, use the

perforated cover of the kit as a scraper.

2. Apply a thin coat of rubber patching cement

evenly over the roughened surface and allow it to dry.

3. From the kit, choose a patch of the proper size

that is about 3/4 inch larger than the hole in the tube from

the kit. Remove the protective covering from the sticky

side of the patch; place the patch over the hole, and rub

it down firmly.

4. Inflate the tube with enough air to check for

leaks. If you cannot hear or feel air escaping from the

patch, you can make another check by inserting the

patched area in water. If no escaping air bubbles are

noticed, the tube may be dried and replaced in the tire

or stored.

tube, the burning material is ignited, allowed to burn,

and then removed after cooling for at least 5 minutes.

After this, examine the completed patch to see if the

edges of the patching material are attached securely to

the tube. Then install the valve core and test the tube.

Hot patches of assorted sizes are supplied in kits similar

to the cold patch kits. You will also find pressure clamps

and roughening tools in the hot patch kits.

TIRE ROTATION

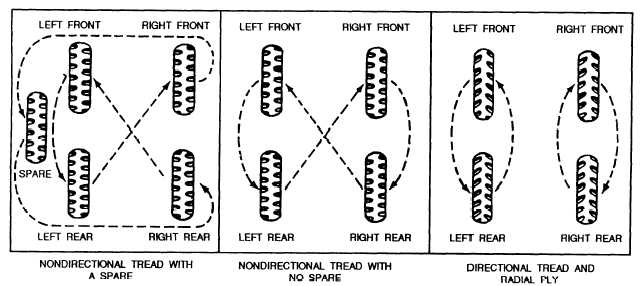

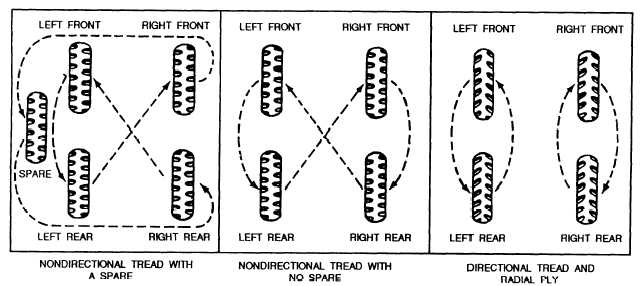

Rotating tires or changing them from one wheel to

another so they wear evenly is recommended by the

manufacturer. Tire rotation is performed to the

manufacturer’s specification for each vehicle.

Examples of tire rotations are shown in figure 3-37.

TIRE SAFETY

Hot Patches

Hot patches consist of a slow burning block of fuel

held in a notched metal pan on the bottom of which is a

patch of uncured rubber. To apply a hot patch, follow

the manufacturer’s instructions on the kit.

Although methods of applying patches vary with

the clamping devices provided and the shape of the

patch, you clean and roughen the tube just as you did in

applying the cold patch. When the patching unit is

placed in the notches of the patch and clamped to the

The tire shop in most commands is supervised by

the maintenance supervisor. When you are assigned to

the tire shop, the maintenance supervisor should ensure

you are briefed on tire safety by either the shop

supervisor, the tire shop foreman, or the crew leader.

People inexperienced in tire repair should only

repair tires when under the direct supervision of an

experienced person. Additionally, always refer to the

appropriate manufacturer’s manuals for directions and

instructions and remember: SAFETY COMES FIRST.

Figure 3-37.-Tire and wheel rotation.

3-20