triangular set of paired dump arms. The other two angles

of the arms are hinged to the bucket cylinder rod and to

the dipper stick.

Dump arms supply the required around-a-curve

reach and prevent the cylinder from being pulled in

against the dipper stick when extending. The arm is

necessary, because the bucket has such an extended arc

of rotary movement around the dipper stick hinge that

the piston arm could not follow it. When the hydraulic

cylinder is extended, the bucket teeth move inward in a

curling or digging motion. When the hydraulic cylinder

is retracted, the bucket dumps, opens, or extends.

Bucket

The bucket can be attached to the bucket mounting

in a variety of ways. One way is the slow process of

removing cotter pins and manually driving out hinge

pins to change the attachment. Another way is a

“quick-latch” mounting where the pins are retained in

the attachment and the quick-latch mounting latches on

the pins and is secured to the attachment by a large bolt.

A third way is a quick disconnect that uses hydraulic

controlled locking pins that the operator controls from

the cab.

Buckets are supplied in a number of widths, ranging

from 24 to 59 inches or more. A bucket is usually slightly

wider at the opening to reduce friction at the sides when

digging and to allow easier dumping. Narrow buckets

tend to be deep in proportion to width and may fill poorly

in chunky or rocky digging, while wide buckets may

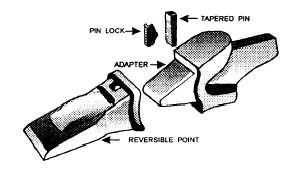

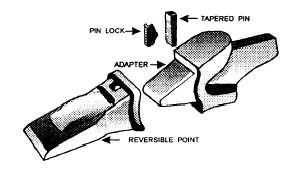

have poor penetration. The digging edge is almost

always equipped with teeth that are removable for

reversing, sharping, or replacement (fig. 9-60).

In the NCF, there are other attachments that are used

in excavator operations. These attachments range from

a grader blade, hydraulic power compactor, perforated

dredge bucket, bull prick (jackhammer), ripper, and so

Figure 9-60.-Detachable tooth.

forth. These attachments are maintained by the

attachment custodian in the transportation yard.

When you are using attachments, remember these

rules: (1) always maintain clearance between the

attachment and the cab to prevent equipment damage

and possible injury; (2) when not in use, store

attachments on a hardstand or wood to keep the items

out of sand, mud, and water; and (3) seal hydraulic lines

and fittings for protection from dirt and moisture.

DIGGING PROCEDURES

If you are unfamiliar with the control or basically

have not operated a backhoe in a while, use a slow

engine speed while you familiarize yourself with each

control. At first, operate the controls separately, then

operate two or more controls at the same time. Basic

digging procedures are as follows:

1. Wear the proper personal protective equipment

for the job, including steel toe safety shoes, a hard hat,

and gloves.

2. Check the ground conditions before you start

to dig.

3. Obtain a digging permit and know the location

of any underground cables and pipelines.

4. Check for overhead obstructions, such as

electric lines, tree limbs, and awnings.

5. Remove large rocks, stumps, or other

obstructions before you begin to dig.

6. When you are digging, use a digging stroke that

will fill the bucket. Full buckets are more efficient and

faster than half-full buckets.

7. Try different digging angles with the bucket to

find the best cutting effort for the material you are

removing. The best digging angle cuts the material as

you fill the bucket.

8. When filling the bucket, keep the bottom of the

bucket parallel with the cut, as shown in figure 9-61,

view A.

9. Let the bucket teeth and the cutting edge cut

through the ground like a knife blade, as shown in figure

9-61, view B.

10. Curl the bucket to retain the cut material, as

shown in figure 9-61, view C.

11. The type of material excavated will determine

how much material can be excavated with each cycle.

9-26