Figure 9-65.—Wheel ditcher.

your machine performs. Figure 9-64 shows two examples

of teeth patterns normally used. When the teeth wear

down about one-half inch and before the face of the

bucket shows wear, ensure the teeth are reversed or

replaced.

NOTE: Always install a complete set of teeth on a

bucket when reversing or replacing teeth.

If only a few new teeth are installed here and there

along the bucket line, the new teeth will cut the most and

wear down much faster than would a whole new set.

However, if only one or two teeth show too much wear

or are broken or chipped, they may be reversed or new

ones installed in their place if the rest of them are in good

shape.

Three types of ditchers used in the NCF are the

wheel ditcher, the ladder ditcher, and the chain ditcher.

The most common ditcher is the ladder ditcher. Read the

operator’s manual to obtain detailed information on the

care, maintenance, and operation of a given ditcher.

WHEEL DITCHER

On the wheel ditcher (fig. 9-65), the digging buckets

are mounted on a large wheel. The wheel is attached to

a frame type of horizontal boom that can be raised and

lowered, and the ditcher has a spoil conveyor for

carrying the excavated material out to either side of the

machine.

To start a cut, lower the turning wheel into the

ground, and then watch the bucket teeth start to dig. As

the ditcher itself is stationary, apply enough pressure to

the buckets so they fill “heaping” without gouging deep

enough to slow the wheel.

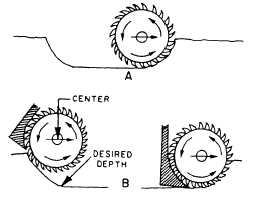

The ditch will have a rounded beginning, as shown

in figure 9-66, views A and B. Be sure the position of

the center of the wheel is over the starting point for the

full depth of the ditch, so the ditcher has enough room

to dig down to the desired depth at the beginning of the

cut (fig. 9-66, view B).

NOTE: Before starting any excavation, you must

ensure a valid digging permit is attained that covers the

area you are tasked to ditch.

Digging

When the wheel is at the correct depth, you should

move the machine forward just fast enough to keep the

buckets reasonably full. Crowding too hard overworks

the engine and strains the digging parts without adding

to the output.

Soft rock usually responds best to a high-wheel

speed with very slow walking speed. If dirt is soft, you

may crowd it so the dirt in excess of the bucket capacity

piles on each side of the ditch without damage.

Experience will help when selecting the right

combination of digging and travel speeds for various

types of soil; however, consult the operator’s manual for

Figure 9-66.-Starting a cut with a wheel ditcher.

9-30