With the ladder ditcher, excavating is done by

buckets attached to the bucket line chain; the chain

travels on the drive sprockets on the boom assembly.

Like the wheel ditcher, the ladder ditcher has a spoil

conveyor to carry the excavated material out to one side

or the other. The radius of a curve depends mainly on

the density of the soil to be excavated. Turns should be

made cautiously at a slow-digging speed and only to

where the boom starts binding between the trench walls.

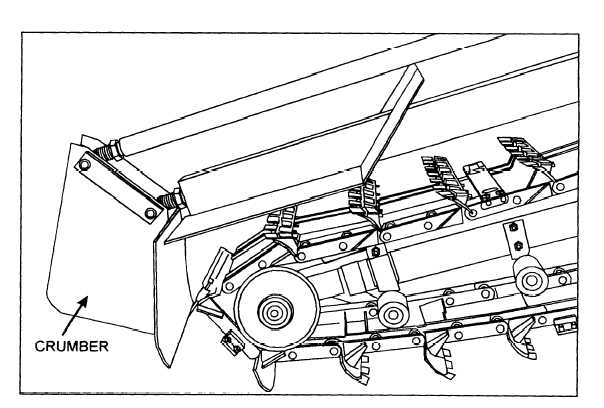

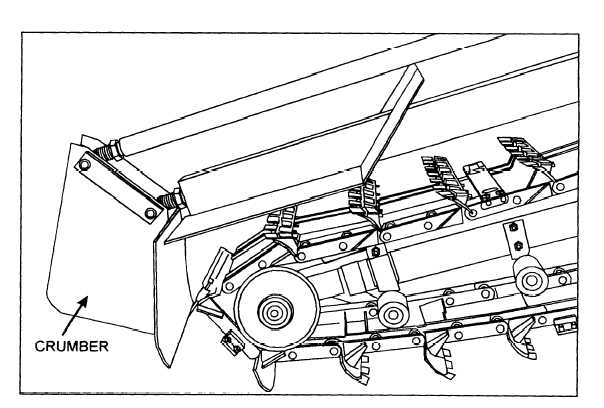

The crumber shown in figure 9-68 has a major job

to clean out and smooth the ditch after the teeth have cut

the material. The crumber is adjustable and should be

adjusted so it will clean the ditch of loose materials

behind the teeth.

CHAIN DITCHER

The chain ditcher, as shown in figure 9-69, has teeth

attached to a chain similar to a chain saw. The chain teeth

pull or drag the cuttings to the surface, rather than lifting

them in a bucket. The cuttings are usually moved back

from the edge of the ditch by rotating augers.

Chain ditchers are ideal for lightweight work, such

as sprinkler systems, gas lines, and small waterlines.

Some of these machines can dig up to 10 inches wide

and 4 feet deep.

CAPABILITIES AND LIMITATIONS OF

DITCHERS

A ditcher can dig earth material ranging in texture

from soft to hard; however, as the material being

excavated increases in hardness, the production rate

decreases. Table 9-1 gives maximum trenching rates for

classes of soils in feet per minute.

A limitation of a wheel, ladder, or chain ditcher is

that ramps are left at the bottom of the trench ends and

around buried objects. To obtain a flat-bottom trench,

you must remove these ramps by hand. The wheel

ditcher digs faster in dense material and is preferred for

cross-country digging where speed is needed.

OPERATING TECHNIQUES

In most ditching work, keep the machine in line and

working at the proper depth. Unable to see the ditch

bottom, you (the operator) must use surface controls.

First, the ditch is surveyed and the depth of cut is

determined by the EAs from the blueprints. You, the EO,

establish a guideline at a fixed and constant distance

above the bottom grade of the trench and offset from the

center line of the trench beyond the track line of the

ditcher.

Figure 9-68.-Crumber.

9-32