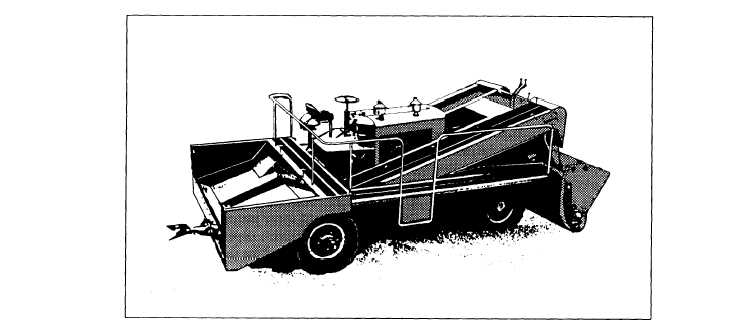

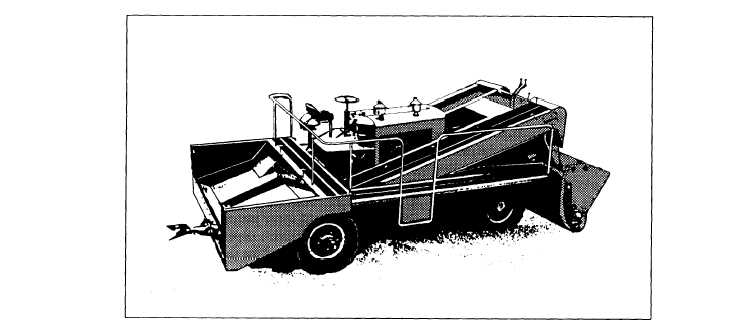

A self-propelled spreader is shown in figure 16-31.

This machine moves forward and makes possible a

uniform and continuous application of cover aggregate,

because it is capable of keeping up with the asphalt

distribute. The spreader is self-powered and has a

receiving hopper in the rear.

Aggregate trucks are

hitched to the spreader, dump their loads into the hopper,

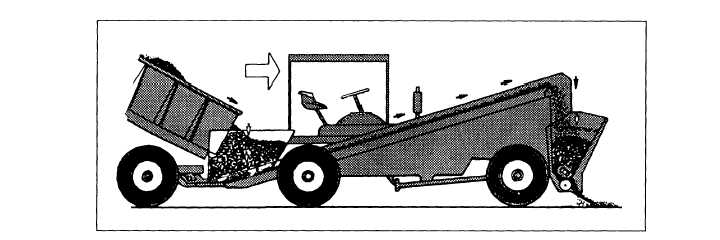

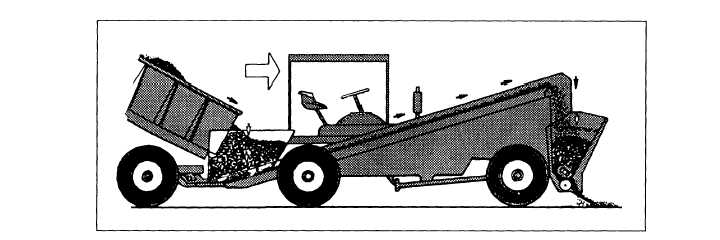

and are pulled by the spreader. Belt conveyors carry the

aggregate to the front of the machine where it is dropped

into the spreading hopper (fig. 16-32). Aggregate flows

over a spread roll onto a screen that permits initial

placement of larger particles on the asphalt, followed by

fine aggregate on top.

Calibration and adjustments for all types of

aggregate spreaders should be made according to the

manufacturer’s instruction and operating manual. Here

are some additional checks that should be made to

ensure good results:

1. A tachometer, used as an aid in maintaining

uniform spreader-box speed, is most helpful.

2. Distribution rates are closely controlled by

measuring off the length that each truckload of

aggregate should cover.

3. A quick check on the rate of application of

aggregate can be made by laying a 1-square-meter

(yard) section of cloth or building paper on the pavement

(or by supporting a shallow l-square-yard box above the

asphalt with nails or screws) and by passing over it with

the spreader. The cloth, paper, or box is then carefully

Figre 16-31.-Self-propelled aggregate spreader.

Figure 16-32.—Flow of aggregate through a self-propelled aggregate spreader.

16-27