lifted and the aggregate on it is weighed. This will give

the weight per square yard of aggregate being spread.

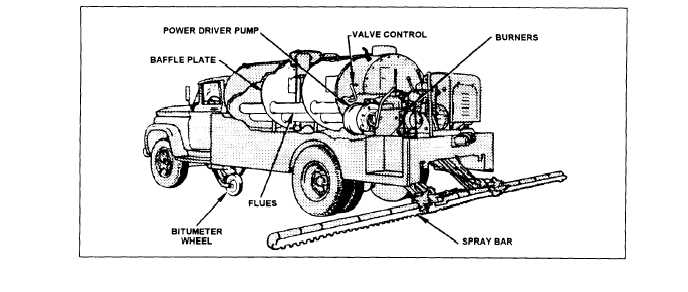

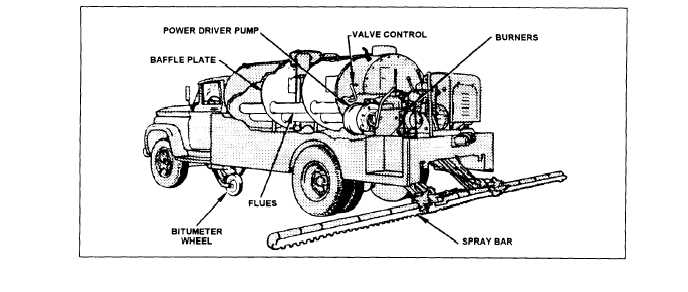

ASPHALT DISTRIBUTOR

The asphalt distributor (fig. 16-33) is a unit

consisting of an insulated storage and heating tank, an

open flame heating system, an asphalt pump, a

low-pressure air blower, and a circulating and spraying

system. Power to operate the components is PTO

driven.

NOTE: The operation of this truck requires the

absolute need for experienced personnel only. Mishaps,

resulting in loss of man-days and equipment, are a direct

result of this factor being overlooked.

Heating System

The air blower provides low-pressure air to atomize

fuel for the burners. The burners heat the tubes, located

in the tank. An asphalt covering must be maintained

over the fire tubes to prevent them from overheating and

causing a fire or explosion. Because the distributor is

mobile, care must be taken to ensure that heating is

performed in a level area that is well-ventilated and that

the distributor truck is not moving at all and is at a

COMPLETE HALT. Whenever you are heating

cutbacks, the asphalt must be circulating at all times.

This is a must to prevent any chance of volatile liquids

overheating around the flues, which can be very

dangerous.

Spray System

The spray system consists of necessary piping, a

series of hand-operated valves to control the flow of

bitumen, and an adjustable length spray bar, capable of

providing coverage from 4 to 14 feet wide. The spray

bar may be the full-circulating or the noncirculating

type, depending on the model of the distributor. The

spray bar may be equipped with either 1/8-inch nozzles

or 3/8-inch nozzles; the 1/8-inch nozzles are used for

most applications. The application rate is controlled by

the length of the spray bar, the pump output, and the

forward speed of the distributor truck.

Spray Bar Adjustments

For normal use, the spray bar of the distributor

should be adjusted, so the vertical axes of the nozzles

are perpendicular to the roadway. Also, each nozzle on

the spray bar should be set at the same angle. The angle

set for each should be between 15 degrees to 30 degrees

of the horizontal axis of the spray bar (fig. 16-34) or

according to manufacturer’s specifications. This action

prevents the fan-shaped spray patterns of the nozzles

from interfering with each other.

Another adjustment that is essential for uniform

prime or tack coat coverage is the adjustment of the

height of the spray bar. As shown in figure 16-35, the

fan-shaped spray patterns from the nozzles overlap to

different degrees, depending on the distance between

the spray bar and the surface to be covered. The spray

bar should be set high enough, usual] y 10 to 12 inches

above the roadway for the surface to receive triple

Figure 16-33.-Asphalt distributor.

16-28