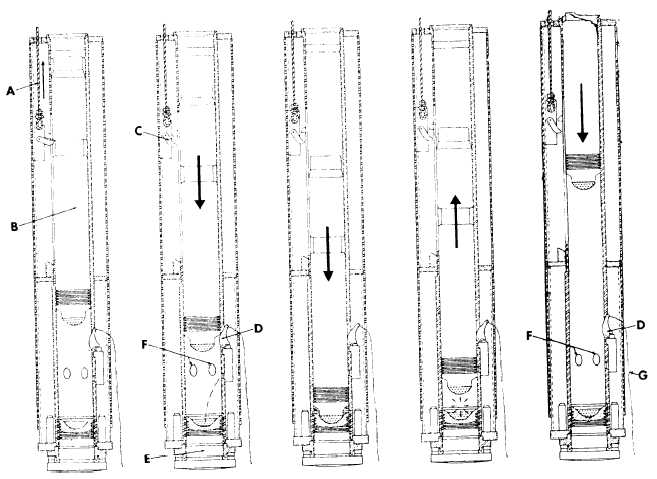

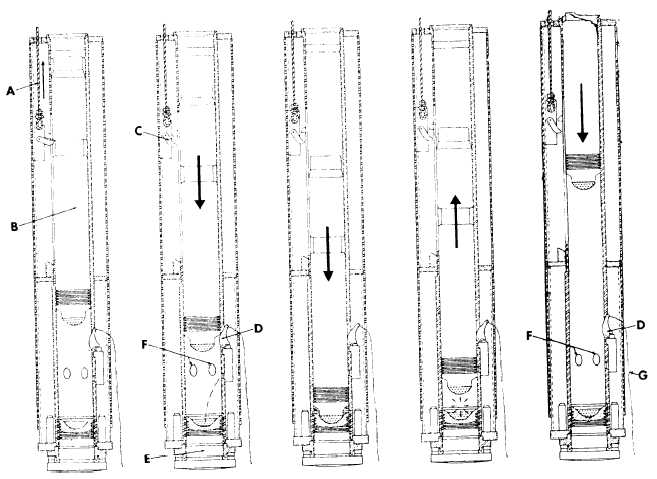

Figure 12-61.-Operating principles of the McKiernan-Terry diesel pile hammer.

precise moment of impact for perfect timing. The fuel

is atomized and splattered into the annular (ring-shaped)

zone between the ram and the anvil and is ignited by the

heat of compression.

The resulting explosive force drives the ram

piston upward and the pile downward and adds a push

to the pile to extend the time of the total effort to drive

the pile.

On the upstroke, the ram piston opens the exhaust

ports (F) to permit scavenging the exhaust gases. The

ram piston continues freely upward until arrested by

gravity.

The length of the stroke varies with the

resistance of the pile.

The greater the resistance, the

longer the stroke.

Having reached the top of its stroke, the ram piston

falls again, repeating the cycle. The hammer is stopped

by pulling a rope (G) that disengages the fuel pump cam

(D).

TRIP MECHANISM.— The trip mechanism (fig.

12-62) is an off-center linkage mechanism located at the

rear of the hammer, designed to lift and drop the ram for

starting. Additionally, the trip mechanism lifts and

lowers the hammer in the leads. The trip mechanism is

connected to a single line from the crane. Lowering the

trip mechanism to the bottom of its stroke engages the

lifting lever that lifts the ram. When the crane lifts the

trip mechanism and ram piston past the upper stops, the

finger of the trip lever is rotated clockwise around the

trip lever pin, thus freeing the ram piston. The trip

mechanism is held in the upper position while the

hammer is in operation.

The safety link in the trip mechanism is designed to

break or bend should the operator lower the trip

mechanism to low and engage the lifting lever while the

hammer is in operation.

The safety link prevents

damaging the trip mechanism or ram. If the safety link

is broken while the hammer is in operation, the hammer

will continue to operate; however, once the hammer is

shut down, the safety link must be replaced before the

hammer can be restarted.

12-43