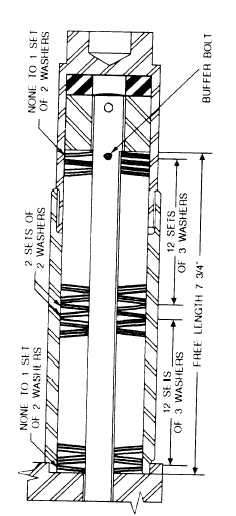

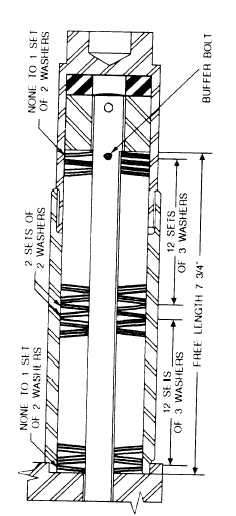

Figure 12-64.-Buffer bolt.

small plungers.

A weighted piston rests on these

plungers. Ajar of the hammer while in operation forces

the piston and plunger down and thus drives a small

amount of oil past the ball check valves and into the feed

lines. Two of the feed lines have terminal checks that

hold back the high pressure of the combustion chamber.

A small pipe plug is provided at each terminal to observe

the flow of oil.

NOTE: Fill the oil reservoir with high temperature,

high detergent No. 30 to No. 40 viscosity diesel engine

lubricating oil with a flash point of 425° to 450°.

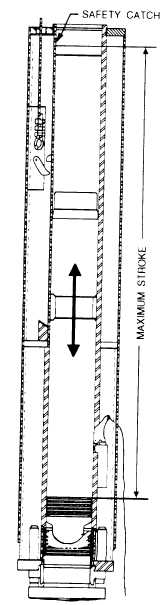

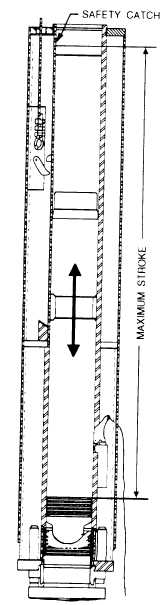

CYLINDER.— The cylinder is a stress-relieved

weldment made from steel tubing and plate with a bore

specifically chrome-plated to prevent seizing, galling,

and rapid wear. The shape of the shell forms a fuel and

oil tank as well as protection for the fuel and oil pumps,

lines, and trip mechanism. Cover plates, front and back

provide easy access to the components. For safety in

transporting and rigging the hammer, the ram piston is

locked in place by a travel plug found midway on the

front of the hammer. This plug should be removed when

the hammer is rigged and ready for operation and should

Figure 12-65.-Maximum ram-piston overstroke.

be replaced when the hammer is removed from the leads

or is laid horizontal. The ram piston is a chrome-steel

forging that has eight compression rings.

BASE ASSEMBLY.— The anvil block in the base

assembly group is held in place by buffer bolts and has

compression rings identical to those on the ram piston

(fig. 12-64). Radial thrust or side thrust to the hammer

is transmitted to the leads through the thrust bearing. A

vibration damper, concealed under a shroud, isolates the

cylinder from the shock vibration of the anvil. Buffer

bumpers absorb the recoil from the Belleville washer

type of buffer springs connected to the anvil by buffer

bolts, dampening overtravel and holding the hammer

together. Pins lock the buffer compression nuts to the

buffer bolts and are held captive by the buffer housing

12-46