damaged or the gas pressure has dropped

abnormally due to a gas leakage.

Pay attention to the yawing of the drill

mounting. Violent yawing of the drill mounting

is caused by improper feed pressure. Adjust the

feed force by using the feed pressure adjusting

valve.

NOTE: Improper feed pressure shortens the life of

the feed chain, the rod, the sleeve, and the shank. It also

results in poor penetration rates.

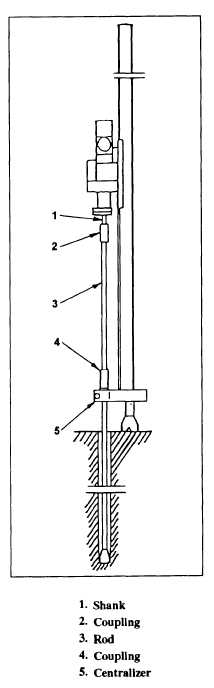

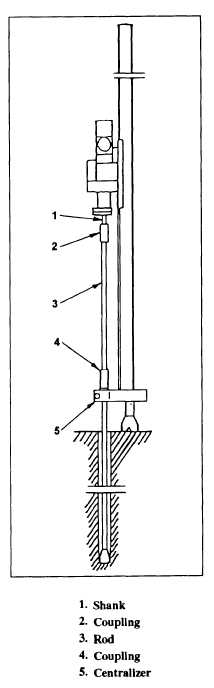

ADDING EXTENSION RODS.— Components of

the rock drill, used when adding or removing extension

rods, are shown in figure 14-26.

Adding extension rods, commonly called drill steel,

is performed as follows:

1. Feed the drifter down and hold the coupling on

top of the centralizer. Engage the drifter hammer until

the coupling is loose.

2. Reverse rotate and allow the drifter to back out

of the coupling, then run the drifter to the top of the drill

guide. Be sure to grease the drifter shank or tamper bar,

and ensure the coupling remains on the drill steel down

in the borehole.

3. Attach another coupling to the drifter shank or

tamper bar. Add additional drill steel; forward rotate

until all is coupled.

4. Lift the coupling off the centralizer. Then open

the centralizer and continue drilling until the coupling

has completely passed the centralizer. Once the

coupling has passed, close the centralizer around the

drill steel.

REMOVING EXTENSION RODS.— Once the

rock drill has reached the desired depth, removing the

extension rods is performed as follows:

1. Clean the hole completely before removing the

drill steel.

2. Move the rotation control lever to the neutral

position to stop rotation.

3. Place the coupling on top of the centralizer, and

allow the drill to hammer on the shank to loosen the

coupling threads.

4. Shut off the drill.

5. Reverse rotate the steel from the coupling.

Figure 14-26.-Components of the drill guide.

NOTE: Keep an eye on the coupling that connects

the drill shank to the drill steel. This coupling will work

loose faster than the lower coupling and could fall.

6. Run the drifter down to the coupling that is

resting on the centralizer.

7. Forward rotate the drifter into the coupling.

8. Run the drifter with the attached coupling and

drill steel to the top of the drill guide. To remove

14-21