the crane unsafe, the operator must secure the crane and

notify the crane crew supervisor.

The Operator’s Daily PM Report, NAVFAC Form

11260/4, is also used with the ODCL when performing

the crane prestart inspection. The ODCL is turned in to

the crane crew supervisor at the end of each day or shift

for reviewing and signing. The NAVFAC Form 11260/4

is turned in to dispatch. As outlined in the NAVFAC

P-307, the minimum requirement for retaining ODCLs

is those completed during the current month and during

the previous month of operation.

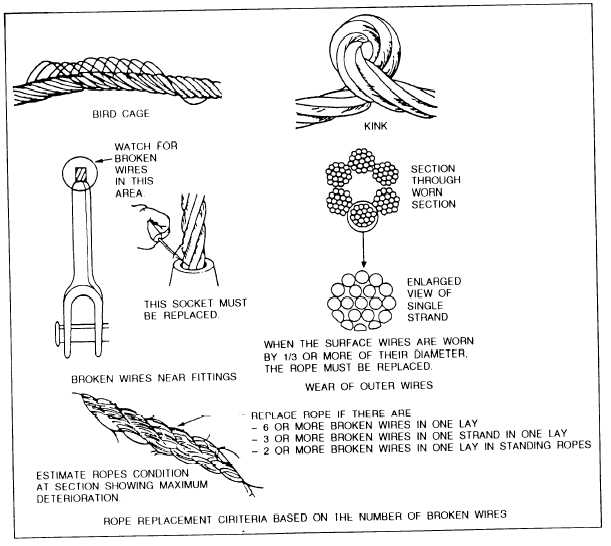

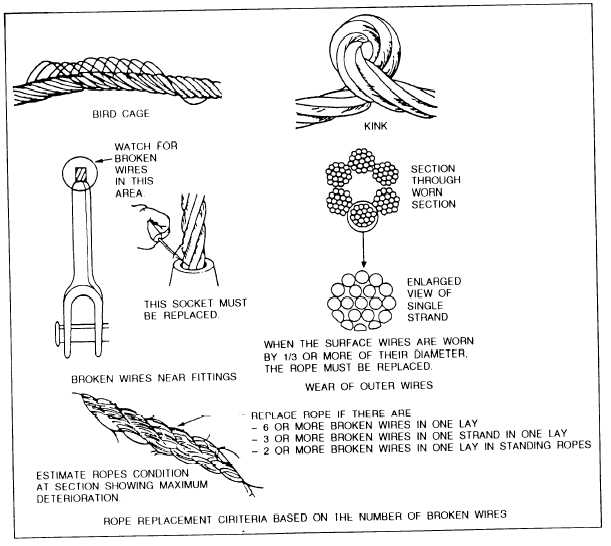

Wire Rope Inspection

Part of the ODCL inspection is the thorough

inspection of all wire rope before using a crane. All

running rope in continuous service must be visually

inspected for crushing, kinking, corrosion or other

damage, broken wires, and proper lubrication (fig.

12-36).

Other areas to inspect are wire rope sockets, swage

fittings, swivels, pendants, and securing hardware for

wear. Hoist drum end fittings need only be disconnected

or disassembled when experience or visible indications

deem it necessary.

The exact time for replacement of wire rope cannot

be given because many variables are involved; however,

safety depends upon the use of good judgment in

evaluating wire rope.

The following conditions are reasons for wire rope

replacement:

1. Running ropes. six or more broken wires

randomly distributed, broken or torn wires in one lay, or

three broken wires in one strand in one lay. Replace end

Figure 12-36.—Common wire rope defects.

12-23