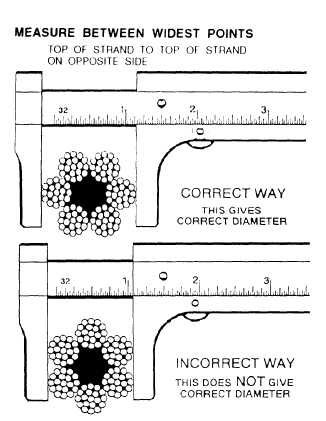

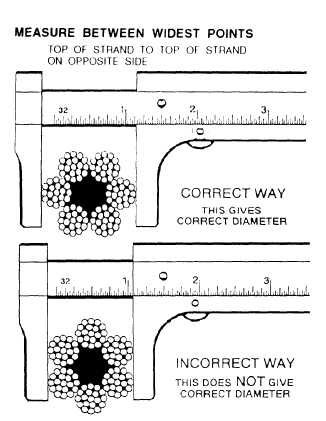

Figure 12-37.—Measuring wire rope.

connections when there are any broken wires adjacent

to the end connection.

2. Boom pendant wire ropes. More than two

broken wires in one lay in sections beyond the end

connection or one or more broken wires at an end

connection.

3. Kinks or crushed sections. Severe kinks or

crushed rope in straight runs where the wire rope core

is forced through the outer strands.

4. Flattened section.

Flat sections where the

diameter across the flat section is less than five sixths of

the original diameter.

5. Wire rope wear. Measure wire rope with wire rope

calipers (fig. 12-37) to check for wear accurately. Replace

why rope that has wear of one third of the original diameter

of outside individual wires. A crescent wrench can be used

as an expedient means to measure wire rope.

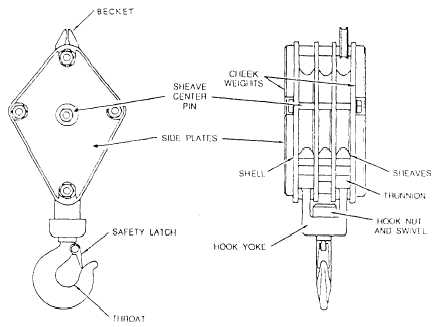

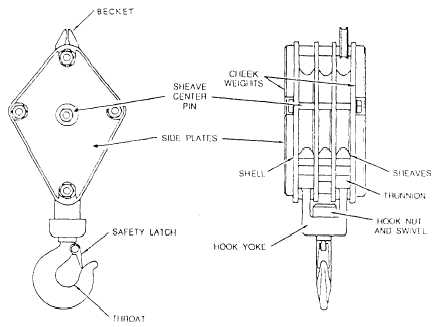

Hook Block Inspection

The hook block and the hook are part of the ODCL

inspection. The operator must inspect the hook block

for cleanliness, binding sheaves, damaged or worn

sheaves, worn or distorted sheave pins, broken bolts,

and worn cheek weights (fig. 12-38).

The hook is inspected for damage, excessive wear

to the hook safety latch, hook swivel trunnions, thrust

collar, and securing nut. Also, the hook is inspected for

damage or missing lubrication fittings, proper

lubrication, cracks and gouges, and if visibly bent or

twisted.

Sheave Inspection

The sheaves inspection (fig. 12-39) is the inspection

for wear and damage, wear in the wire rope sheave

groove, loose or damage sheave guards, and worn

bearings and pins. Sheaves rotate on either bearings or

bushings that are inspected for discoloration (due to

Figure 12-38.-Hook and block inspection points.

12-24