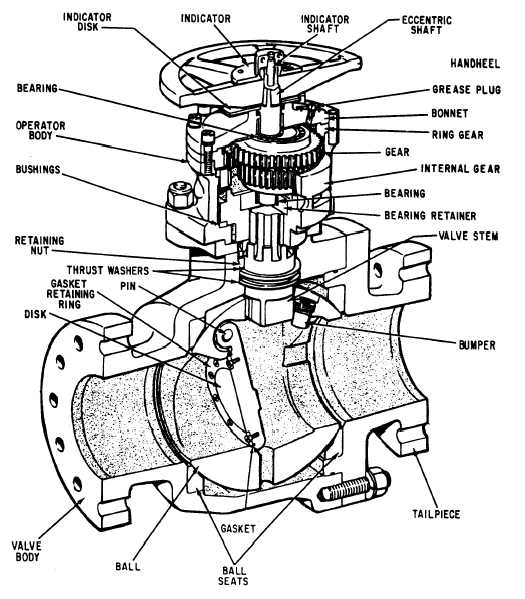

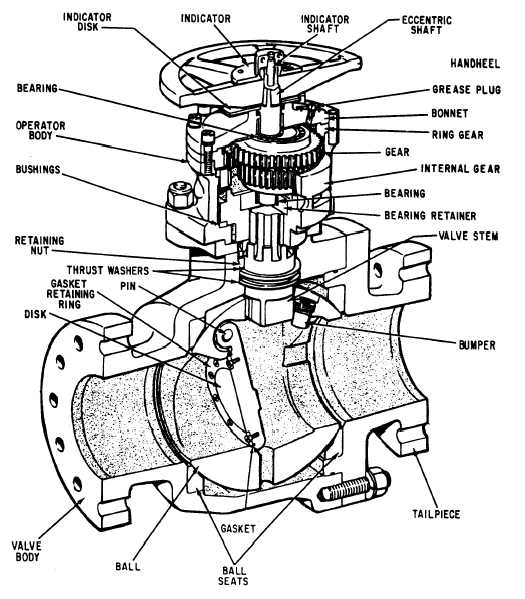

same function as the disk in other valves. As the

valve handle is turned to open the valve, the ball

rotates to a point where part or all of the hole

through the ball is in line with the valve body inlet

and outlet, allowing fluid to flow through the

valve. When the ball is rotated so the hole is

perpendicular to the flow openings of the valve

body, the flow of fluid stops.

Most ball valves are the quick-acting type.

They require only a 90-degree turn to either

completely open or close the valve. However,

many are operated by planetary gears. This type

of gearing allows the use of a relatively small

handwheel and operating force to operate a fairly

large valve. The gearing does, however, increase

the operating time for the valve. Some ball valves

also contain a swing check located within the ball

to give the valve a check valve feature. Figure 6-2

shows a ball-stop, swing-check valve with a

planetary gear operation.

In addition to the ball valves shown in figures

6-1 and 6-2, there are three-way ball valves that

are used to supply fluid from a single source to

one component or the other in a two-component

system (fig. 6-3).

Figure 6-2.—Typical ball-stop, swing-check valve.

6-2