CHAPTER 6

VALVES

It is all but impossible to design a practical

fluid power system without some means of

controlling the volume and pressure of the fluid

and directing the flow of fluid to the operating

units. This is accomplished by the incorporation

of different types of valves. A valve is defined as

any device by which the flow of fluid may be

started, stopped, or regulated by a movable part

that opens or obstructs passage. As applied

in fluid power systems, valves are used for

controlling the flow, the pressure, and the

direction of the fluid flow.

Valves must be accurate in the control of fluid

flow and pressure and the sequence of operation.

Leakage between the valve element and the valve

seat is reduced to a negligible quantity by

precision-machined surfaces, resulting in carefully

controlled clearances. This is one of the very

important reasons for minimizing contamination

in fluid power systems. Contamination causes

valves to stick, plugs small orifices, and causes

abrasions of the valve seating surfaces, which

results in leakage between the valve element and

valve seat when the valve is in the closed position.

Any of these can result in inefficient operation

or complete stoppage of the equipment.

Valves may be controlled manually, electri-

cally, pneumatically, mechanically, hydraulically,

or by combinations of two or more of these

methods. Factors that determine the method of

control include the purpose of the valve, the

design and purpose of the system, the location of

the valve within the system, and the availability

of the source of power.

The different types of valves used in fluid

power systems, their classification, and their

application are discussed in this chapter.

CLASSIFICATIONS

Valves are classified according to their use:

flow control, pressure control, and directional

control. Some valves have multiple functions that

fall into more than one classification.

FLOW CONTROL VALVES

Flow control valves are used to regulate the

flow of fluids in fluid-power systems. Control of

flow in fluid-power systems is important because

the rate of movement of fluid-powered machines

depends on the rate of flow of the pressurized

fluid. These valves may be manually, hydrau-

lically, electrically, or pneumatically operated.

Some of the different types of flow control

valves are discussed in the following paragraphs.

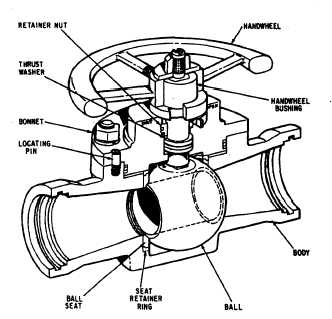

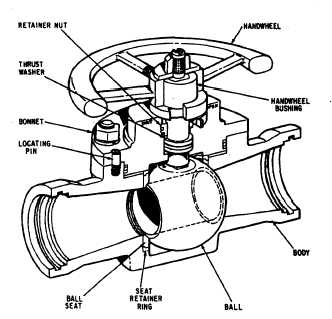

BALL VALVES

Ball valves, as the name implies, are stop

valves that use a ball to stop or start a flow of

fluid. The ball, shown in figure 6-1, performs the

Figure 6-1.—Typical ball valve.

6-1