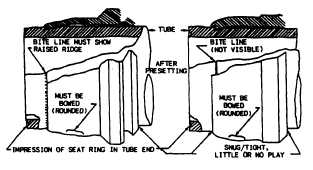

Figure 5-21.—Ferrules installed on tube, preset and removed

for inspection.

b. For recessed-type ferrules, the leading

edge must be snug against the tube OD. Determine

this visually and by attempting to rock the ferrule

on the tube.

3. Ensure that the nut end of the ferrule (both

types) is collapsed around the tube to provide

support against bending loads and vibration.

4. The ferrule (both types) must have little or

no play along the direction of the tube run. Check

this by trying to move the ferrule back and forth

by hand. The ferrule will often be free to rotate

on the tubing; this does not affect its function.

5. For flush-type ferrules, check that the gap

between the raised metal ridge and the cutting end

of the ferrule stays the same while the ferrule is

rotated. (Omit this check for recessed-type ferrules

or if the flush-type ferrule will not rotate on the

tube).

6. Check that the middle portion of the ferrule

(both types) is bowed or sprung into an arc. The

leading edge of the ferrule may appear flattened

into a cone shape; this is acceptable as long as

there is a bowed section near the middle of the

ferrule. If the whole leading section of the ferrule

is flattened into a cone with no bowed section,

the ferrule (and possibly the fitting body, if used)

has been damaged by overtightening and will not

seal reliably.

Final Assembly

When you make a final assembly in the

system, use the following installation procedure:

1. Lubricate all threads with a liquid that is

compatible with the fluid to be used in the system.

2. Place the tube assembly in position and

check for alignment.

3. Tighten the nut by hand until you feel an

increase in resistance to turning. This indicates

that the sleeve or ferrule pilot has contacted the

fitting.

4. If possible, use a torque wrench to tighten

flareless tubing nuts. Torque values for specific

installations are usually listed in the applicable

technical publications. If it is not possible to use

a torque wrench, use the following procedures for

tightening the nuts:

After the nut is handtight, turn the nut 1/6

turn (one flat on a hex nut) with a wrench. Use

a wrench on the connector to prevent it from

turning while tightening the nut. After you install

the tube assembly, have the system pressure tested.

Should a connection leak, you may tighten the

nut an additional 1/6 turn (making a total of 1/3

turn). If, after tightening the nut a total of 1/3

turn, leakage still exists, remove the assembly and

inspect the components of the assembly for scores,

cracks, presence of foreign material, or damage

from overtightening.

NOTE: Overtightening a flareless-tube nut

drives the cutting edge of the sleeve or ferrule

deeply into the tube, causing the tube to be

weakened to the point where normal vibration

could cause the tube to shear. After you complete

the inspection (if you do not find any dis-

crepancies), reassemble the connection and repeat

the pressure test procedures.

CAUTION: Do not in any case tighten the

nut beyond 1/3 turn (two flats on the hex nut);

this is the maximum the fitting may be tightened

without the possibility of permanently damaging

the sleeve or the tube.

CONNECTORS FOR

FLEXIBLE HOSE

As stated previously, the fabrication of flexible

hose assemblies is covered in applicable training

manuals, technical publications, and NAVAIR

01-1A-20. There are various types of end fittings

for both the piping connection side and the hose

5-17