caused personnel injury, damage to equip-

ment, and unnecessary interruption of

propulsion power.

1. Cut the tubing square and lightly deburr

the inside and outside corners. For corrosion

resisting steel (CRES) tubing, use a hacksaw rather

than a tubing cutter to avoid work hardening the

tube end. For CRES, and if necessary for other

materials, dress the tube end smooth and square

with a file. Tube ends with irregular cutting marks

will not produce satisfactory seating surface

impressions.

2. Test the hardness of the ferrule by making

a light scratch on the tubing at least 1/2 inch back

from the tube end, using a sharp corner on the

ferrule. If the ferrule will not scratch the tube,

no bite will be obtained. This test maybe omitted

for flush-type ferrules where the bite will be

visible. Moderate hand pressure is sufficient for

producing the scratch.

3. Lubricate the nut threads, the ferrule

leading and trailing edges, and the preset tool

threads with a thread lubricant compatible with

the system. Slide the nut onto the tubing so the

threads face the tube end. Note whether the

ferrule is a flush type or recessed type (fig. 5-19),

and slide the ferrule onto the tube so the cutting

edge is toward the tube end (large end toward the

nut).

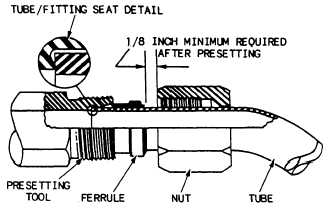

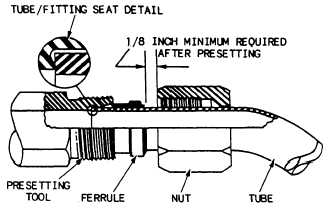

4. Bottom the end of the tubing in the

presetting tool. Slide the ferrule up into the

presetting tool, and confirm that the nut can be

moved down the tube sufficiently to expose at

least 1/8 inch of tubing past the ferrule after the

presetting operation (fig. 5-20) to allow for

inspection of the ferrule.

5. While keeping the tube bottomed in the

presetting tool, tighten the nut onto the fitting

body until the ferrule just grips the tube by

friction. This ring grip point may be identified by

lightly turning the tube or the presetting tool and

slowly tightening the nut until the tube cannot

be turned in the presetting tool by hand.

Mark the nut and the presetting tool at this

position.

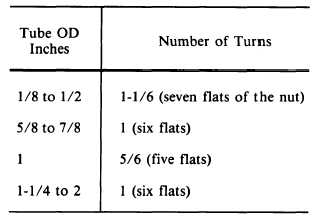

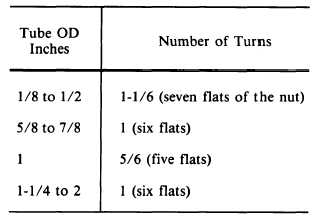

6. Tighten the nut according to the number

of turns given in table 5-3, depending on tube

size.

5-16

Figure 5-20.—Tube and ferrule assembled for preset-

ting, showing nut position required for inspecting

ferrule.

Inspection

Disassemble and inspect the fitting as follows

(mandatory):

1. Ensure that the end of the tubing has an

impression of the presetting tool seat surface

(circular appearing ring) for 360 degrees. A partial

circle, a visibly off-center circle, or a circle broken

by the roughness of the tube end is unsatisfactory.

2. Check for proper bite:

a. For flush-type ferrules, a raised ridge

(fig. 5-21) of tube metal must be visible completely

around the tube at the leading edge of the ferrule.

The best practice is to obtain a ridge about 50

percent of the ferrule edge thickness.

Table 5-3.—Number of Turns