specifications which define the materials and

techniques.

BRAZED CONNECTORS

Silver-brazed connectors are commonly used

for joining nonferrous (copper, brass, and soon)

piping in the pressure and temperature range

where their use is practical. Use of this type of

connector is limited to installations in which the

piping temperature will not exceed 425°F and the

pressure in cold lines will not-exceed 3,000 psi.

The alloy is melted by heating the joint with an

oxyacetylene torch. This causes the alloy insert

to melt and fill the few thousandths of an inch

annular space between the pipe and the fitting.

A fitting of this type which has been removed

from a piping system can be rebrazed into a

system, as in most cases sufficient alloy remains

in the insert groove for a second joint. New alloy

inserts may be obtained for fittings which do not

have sufficient alloy remaining in the insert for

making a new joint.

FLARED CONNECTORS

Flared connectors are commonly used in fluid

power systems containing lines made of tubing.

These connectors provide safe, strong, dependable

connections without the need for threading,

welding, or soldering the tubing. The connector

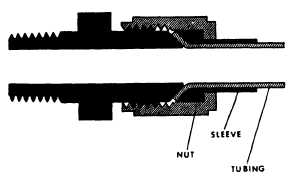

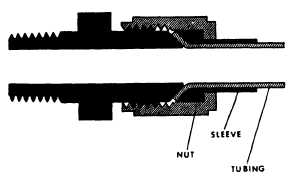

consists of a fitting, a sleeve, and a nut (fig. 5-15).

The fittings are made of steel, aluminum alloy,

or bronze. The fitting used in a connection should

be made of the same material as that of the sleeve,

the nut, and the tubing. For example, use steel

connectors with steel tubing and aluminum alloy

Figure 5-15.—Flared-tube fitting.

connectors with aluminum alloy tubing. Fittings

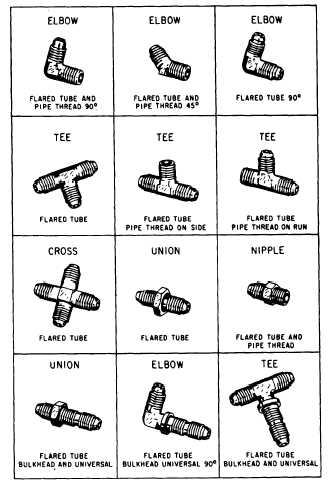

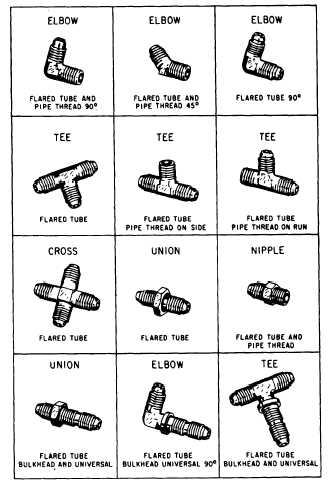

are made in union, 45-degree and 90-degree

elbow, tee, and various other shapes (fig. 5-16).

Tees, crosses, and elbows are self-explanatory.

Universal and bulkhead fittings can be mounted

solidly with one outlet of the fitting extending

through a bulkhead and the other outlet(s) posi-

tioned at any angle. Universal means the fitting

can assume the angle required for the specific

installation. Bulkhead means the fitting is long

enough to pass through a bulkhead and is

designed so it can be secured solidly to the

bulkhead.

For connecting to tubing, the ends of the

fittings are threaded with straight machine threads

to correspond with the female threads of the nut.

In some cases, however, one end of the fitting may

be threaded with tapered pipe threads to fit

Figure 5-16.—Flared-tube fittings.

5-13