3. be designed to give adequate performance and

service for infrequent transient pressure peaks

up to 150 percent of the working pressure of

the hose, and

4. have a safety factor with a burst pressure at

a minimum of 4 times the rated working

pressure.

There are temperature restrictions applied to

the use of hoses. Rubber hose must not be used

where the operating temperature exceeds 200°F.

PTFE hoses in high-pressure air systems must not

be used where the temperature exceeds 350°F.

PTFE hoses in water and steam drain applications

must not be used where the operating temperature

exceeds 380°F.

FABRICATION AND TESTING

The fabrication of flexible hose assemblies is

covered in applicable training manuals, technical

publications, and NAVAIR 01-1A-20. After a

hose assembly has been completely fabricated it

must be cleaned, visually inspected for foreign

materials, and proof tested.

A hose assembly is proof tested by the

application of a nondestructive pressure for a

minimum of 1 minute but not longer than 5

minutes to ensure that it will withstand normal

working pressures. The test pressure, known as

normal proof pressure, is twice the rated working

pressure. While the test pressure is being applied,

the hose must not burst, leak, or show signs

of fitting separation. NAVAIR 01-1A-20 and

NAVSEA S6430-AE-TED-010, volume 1, provide

detailed instructions on cleaning of hoses, cleaning

and test media, proof pressure and proof testing.

After proof testing is completed, the hose must

be flushed and dried and the ends capped or

plugged to keep dirt and other contaminants out

of the hose.

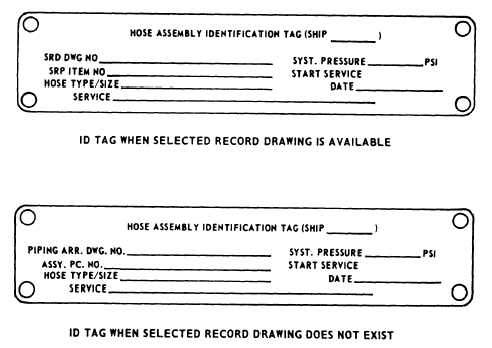

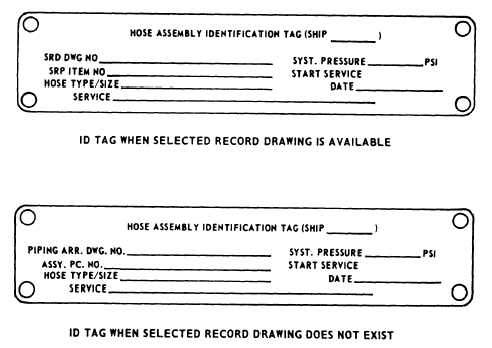

IDENTIFICATION

The final step after fabrication and satisfac-

tory testing of a hose assembly is the attachment

of identification tags as shown in figure 5-11 (for

ships) and in figure 5-12 (for aircraft). The tag

shown in figure 5-12, view B, is used in areas

where a tag maybe drawn into an engine intake.

Hose assemblies to be installed in aircraft fuel and

oil tanks are marked with an approved electric

engraver on the socket-wrench flats with the

required information.

Figure 5-11.—Hose assembly identification tags (ships).

5-10