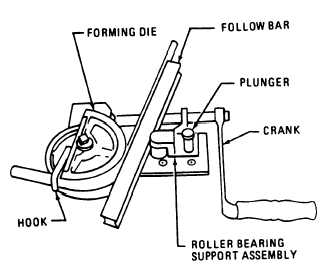

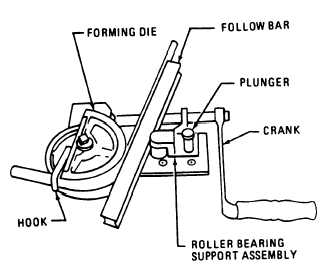

Figure 5-7.—Mechanically operated tube bender.

slide bar is moved around until the mark on the

slide bar reaches the desired degree of bend on

the radius block. See figure 5-6 for the six

procedural steps in

tube bending with the

hand-operated tube bender.

MECHANICAL TUBE BENDER.— The

tube bender shown in figure 5-7 is issued as a kit.

The kit contains the equipment necessary for

bending tubing from 1/4 inch to 3/4 inch in

diameter.

This tube bender is designed for use with

aircraft grade, high-strengths stainless-steel

tubing, as well as all other metal tubing. It is

designed to be fastened to a bench or tripod. The

base is formed to provide a secure grip in a vise.

This type of tube bender uses a hand crank

and gears. The forming die is keyed to the drive

gear and is secured by a screw.

The forming die on the mechanical tube

bender is calibrated in degrees, similarly to the

radius block of the hand bender. A length of

replacement tubing may be bent to a specified

number of degrees or it may be bent to duplicate

a bend either in a damaged tube or in a pattern.

Duplicating a bend of a damaged tube or of a

pattern is done by laying the sample or pattern

on top of the tube being bent and slowly bending

the new tube to the required bend.

Tube Flaring

Tube flaring is a method of forming the end

of a tube into a funnel shape so it can be held by

a threaded fitting. When a flared tube is prepared,

a flare nut is slipped onto the tube and the end

of the tube is flared. During tube installation, the

flare is seated to a fitting with the inside of the

flare against the cone-shaped end of the fitting,

and the flare nut is screwed onto the fitting,

pulling the inside of the flare against the seating

surface of the fitting.

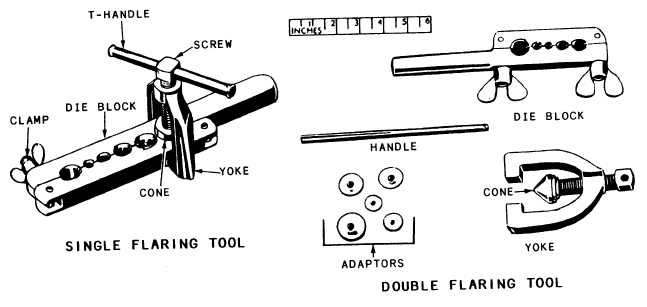

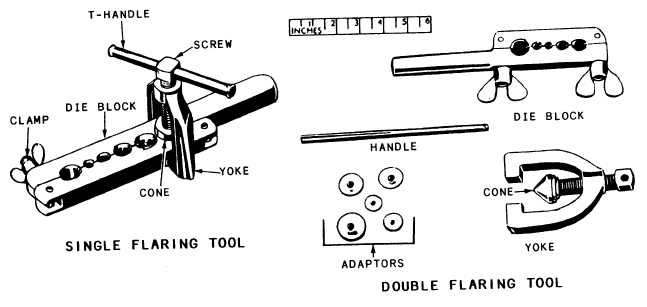

Either of two flaring tools (fig. 5-8) may be

used. One gives a single flare and the other gives

a double flare. The flaring tool consists of a split

die block that has holes for various sizes of tubing,

Figure 5-8.—Flaring tools.

5-7