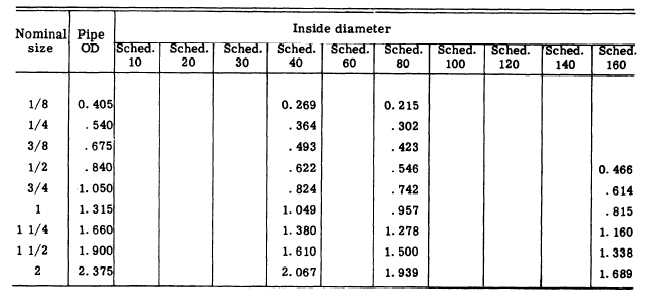

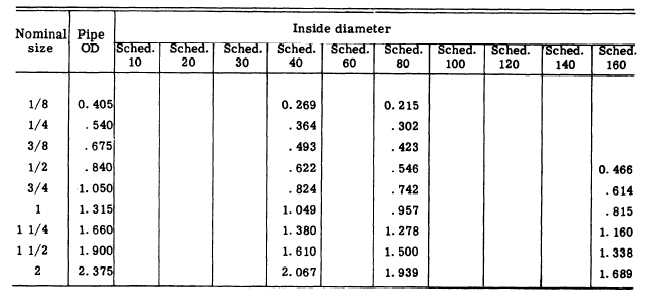

Table 5-1.—Wall Thickness Schedule Designations for Pipe

160 pipe has a 0.815 ID. In each case the OD is

1.315 (table 5-1) and the wall thicknesses are

0.133

0.179

and 0.250

respectively. Note

that the difference between the OD and ID

includes two wall thicknesses and must be divided

by 2 to obtain the wall thickness.

Tubing differs from pipe in its size classi-

fication. Tubing is designated by its actual OD.

(See table 5-2.) Thus, 5/8-inch tubing has an OD

of 5/8 inch. As indicated in the table, tubing is

available in a variety of wall thicknesses. The

diameter of tubing is often measured and

indicated in 16ths. Thus, No. 6 tubing is 6/16 or

3/8 inch, No. 8 tubing is 8/16 or 1/2 inch, and

so forth.

The wall thickness, material used, and ID

determine the bursting pressure of a line or fitting.

The greater the wall thickness in relation to the

ID and the stronger the metal, the higher the

bursting pressure. However, the greater the ID for

a given wall thickness, the lower the bursting

pressure, because force is the product of area and

pressure.

Materials

The pipe and tubing used in fluid power

systems are commonly made from steel, copper,

brass, aluminum, and stainless steel. Each of these

metals has its own distinct advantages or

disadvantages in certain applications.

Steel pipe and tubing are relatively inexpensive

and are used in many hydraulic and pneumatic

systems. Steel is used because of its strength,

suitability for bending and flanging, and

adaptability to high pressures and temperatures.

Its chief disadvantage is its comparatively low

resistance to corrosion.

Copper pipe and tubing are sometimes used

for fluid power lines. Copper has high resistance

to corrosion and is easily drawn or bent. However,

it is unsatisfactory for high temperatures and has

a tendency to harden and break due to stress and

vibration.

Aluminum has many of the characteristics and

qualities required for fluid power lines. It has high

resistance to corrosion and is easily drawn or bent.

In addition, it has the outstanding characteristic

of light weight. Since weight elimination is a vital

factor in the design of aircraft, aluminum alloy

tubing is used in the majority of aircraft fluid

power systems.

Stainless-steel tubing is used in certain areas

of many aircraft fluid power systems. As a general

rule, exposed lines and lines subject to abrasion

or intense heat are made of stainless steel.

An improperly piped system can lead to

serious power loss and possible harmful fluid

5-2