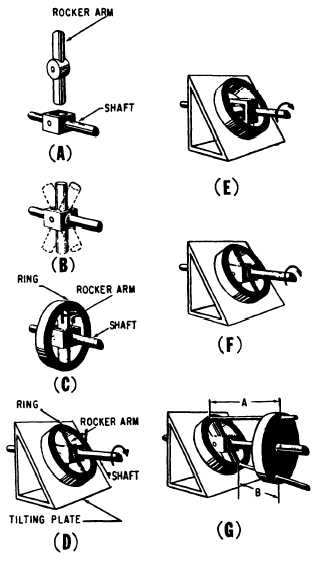

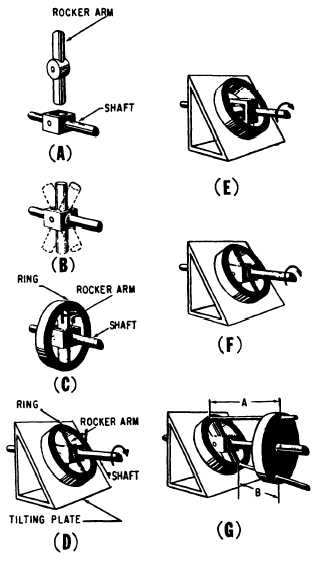

Figure 4-15 is a series of drawings that illustrates

how the universal joint is used in the operation

of this pump.

First, a rocker arm is installed on a horizontal

shaft. (See fig. 4-15, view A.) The arm is joined

to the shaft by a pin so that it can be swung back

and forth, as indicated in view B. Next, a ring is

placed around the shaft and secured to the rocker

arm so the ring can turn from left to right as

shown in view C. This provides two rotary

motions in different planes at the same time and

in varying proportions as may be desired. The

rocker arm can swing back and forth in one arc,

and the ring can simultaneously move from left

Figure 4-15.–Relationship of the universal joint in operation

of the axial piston pump.

to right in another arc, in a plane at right angles

to the plane in which the rocker arm turns.

Next, a tilting plate is added to the assembly.

The tilting plate is placed at a slant to the axis

of the shaft, as depicted in figure 4-15, view D.

The rocker arm is then slanted at the same angle

as the tilting plate, so that it lies parallel to the

tilting plate. The ring is also parallel to, and in

contact with, the tilting plate. The position of the

ring in relation to the rocker arm is unchanged

from that shown in figure 4-15, view C.

Figure 4-15, view E, shows the assembly after

the shaft, still in a horizontal position, has been

rotated a quarter turn. The rocker arm is still in

the same position as the tilting plate and is now

perpendicular to the axis of the shaft. The ring

has turned on the rocker pins, so that it has

changed its position in relation to the rocker arm,

but it remains parallel to, and in contact with, the

tilting plate.

View F of figure 4-15 shows the assembly after

the shaft has been rotated another quarter turn.

The parts are now in the same position as shown

in view D, but with the ends of the rocker arm

reversed. The ring still bears against the tilting

plate.

As the shaft continues to rotate, the rocker

arm and the ring turn about their pivots, with each

changing its relation to the other and with the ring

always bearing on the plate.

Figure 4-15, view G, shows a wheel added to

the assembly. The wheel is placed upright and

fixed to the shaft, so that it rotates with the shaft.

In addition, two rods, A and B, are loosely

connected to the tilting ring and extend through

two holes standing opposite each other in the fixed

wheel. As the shaft is rotated, the fixed wheel

turns perpendicular to the shaft at all times. The

tilting ring rotates with the shaft and always

remains tilted, since it remains in contact with the

tilting plate. Referring to view G, the distance

along rod A, from the tilting ring to the fixed

wheel, is greater than the distance along rod B.

As the assembly is rotated, however, the distance

along rod A decreases as its point of attachment

to the tilting ring moves closer to the fixed wheel,

while the distance along rod B increases. These

changes continue until after a half revolution, at

which time the initial positions of the rods have

been reversed. After another half revolution, the

two rods will again be in their original positions.

As the assembly rotates, the rods move in and

out through the holes in the fixed wheel. This is

the way the axial piston pump works. To get a

pumping action, place pistons at the ends of the

4-13