rods, beyond the fixed wheel, and insert them into

cylinders. The rods must be connected to the

pistons and to the wheel by ball and socket joints.

As the assembly rotates, each piston moves back

and forth in its cylinder. Suction and discharge

lines can be arranged so that liquid enters the

cylinders while the spaces between the piston

heads and the bases of the cylinders are increasing,

and leaves the cylinders during the other half of

each revolution when the pistons are moving in

the opposite direction.

The main parts of the pump are the drive

shaft, pistons, cylinder block, and valve and swash

plates. There are two ports in the valve plate.

These ports connect directly to openings in the

face of the cylinder block. Fluid is drawn into one

port and forced out the other port by the

reciprocating action of the pistons.

IN-LINE VARIABLE-DISPLACEMENT

AXIAL PISTON PUMP.— When the drive shaft

is rotated, it rotates the pistons and the cylinder

block with it. The swash plate placed at an angle

causes the pistons to move back and forth in the

cylinder block while the shaft, piston, cylinder

block, and swash plate rotate together. (The shaft,

piston, cylinder block, and swash plate together

is sometimes referred to as the rotating group or

assembly.) As the pistons reciprocate in the

cylinder block, fluid enters one port and is forced

out the other.

Figure 4-13 shows piston A at the bottom of

its stroke. When piston A has rotated to the

position held by piston B, it will have moved

upward in its cylinder, forcing fluid through the

outlet port during the entire distance. During the

remainder of the rotation back to it original

position, the piston travels downward in the

cylinder. This action creates a low-pressure area

in the cylinder. The difference in pressure between

the cylinder inlet and the reservoir causes fluid

to flow into the inlet port to the cylinder. Since

each one of the pistons performs the same

operation in succession, fluid is constantly being

taken into the cylinder bores through the inlet port

and discharged from the cylinder bores into

the system. This action provides a steady,

nonpulsating flow of fluid.

The tilt or angle of the swash plate determines

the distance the pistons move back and forth in

their cylinders; thereby, controlling the pump

output.

When the swash plate is at a right angle to the

shaft, and the pump is rotating, the pistons do

not reciprocate; therefore, no pumping action

takes place. When the swash plate is tilted away

from a right angle, the pistons reciprocate and

fluid is pumped.

Since the displacement of this type of pump

is varied by changing the angle of the tilting box,

some means must be used to control the changes

of this angle. Various methods are used to control

this movement—manual, electric, pneumatic, or

hydraulic.

STRATOPOWER PUMP.— Another type of

axial piston pump, sometimes referred to as an

in-line pump, is commonly referred to as a

Stratopower pump. This pump is available

in either the fixed-displacement type or the

variable-displacement type.

Two major functions are performed by the

internal parts of the fixed-displacement Strato-

power pump. These functions are mechanical

drive and fluid displacement.

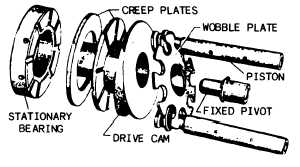

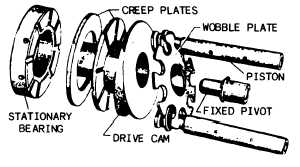

The mechanical drive mechanism is shown in

figure 4-16. In this type of pump, the pistons and

block do not rotate. Piston motion is caused by

rotating the drive cam displacing each piston the

full height of the drive cam during each revolution

of the shaft. The ends of the pistons are attached

to a wobble plate supported by a freed center pivot

and are held inconstant contact with the cam face.

As the high side of the rotating drive cam

depresses one side of the wobble plate, the other

side of the wobble plate is withdrawn an equal

amount, moving the pistons with it. The two creep

plates are provided to decrease wear on the

revolving cam.

A schematic diagram of the displacement of

fluid is shown in figure 4-17. Fluid is displaced

by axial motion of the pistons. As each piston

advances in its respective cylinder block bore,

pressure opens the check valve and a quantity of

fluid is forced past it. Combined back pressure

and check valve spring tension close the check

Figure 4-16.—Mechanical drive—Stratopower pump.

4-14