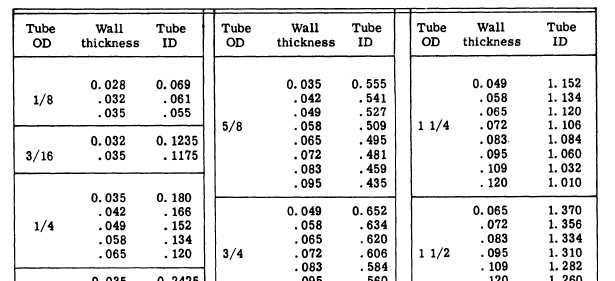

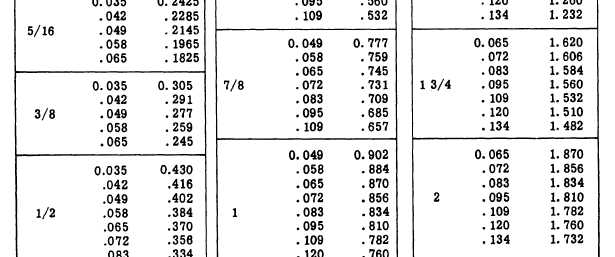

Table 5-2.—Tubing Size Designation

contamination. Therefore in maintenance and

PREPARATION OF PIPES

repair of fluid power system lines, the basic design

AND TUBING

requirements must be kept in mind. Two primary

requirements are as follows:

1. The lines must have the correct ID to

provide the required volume and velocity of flow

with the least amount of turbulence during all

demands on the system.

2. The lines must be made of the proper

material and have the wall thickness to provide

sufficient strength to both contain the fluid at the

required pressure and withstand the surges of

pressure that may develop in the system.

Fluid power systems are designed as compactly

as possible, to keep the connecting lines short.

Every section of line should be anchored securely

in one or more places so that neither the weight

of the line nor the effects of vibration are carried

on the joints. The aim is to minimize stress

throughout the system.

Lines should normally be kept as short and

free of bends as possible. However, tubing should

not be assembled in a straight line, because a bend

tends to eliminate strain by absorbing vibration

and also compensates for thermal expansion and

5-3