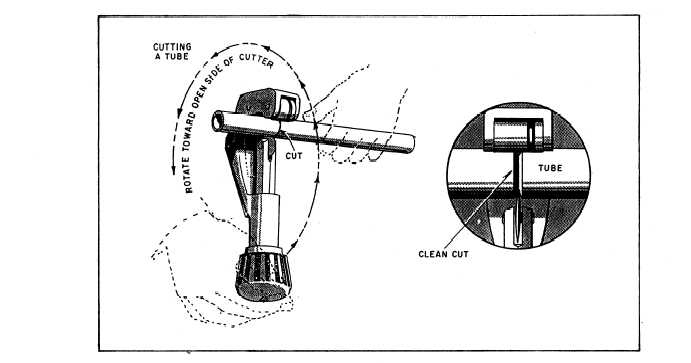

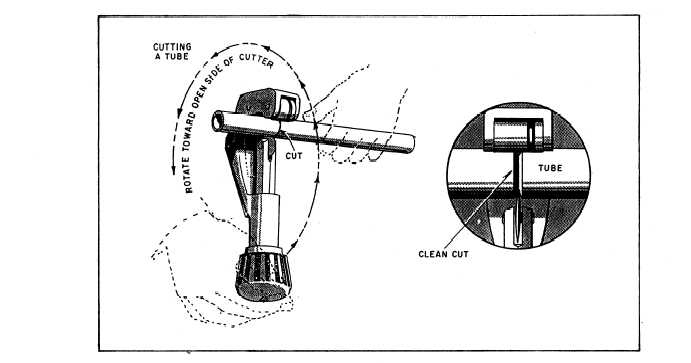

Figure 5-3.—Tube cutting.

5. Tighten the drive screw 1/8 to 1/4 turn. Do

not overtighten the drive screw. Overtightening

can damage soft tubing or cause excessive wear

or breakage of the cutter wheel in hard tubing.

6. Swing the ratchet handle back and forth

through the available clearance until there is a

noticeable ease of rotation. Avoid putting side

force on the cutter handle. Side force will cause

the cutter wheel to break.

7. Tighten the drive screw an additional 1/8

to 1/4 turn and swing the ratchet handle back and

forth, retightening the drive screw as needed until

the cut is completed. The completed cut should

be 1/2 degree square to the tube centerline.

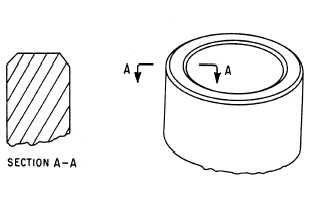

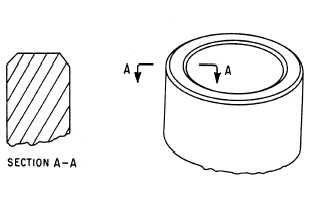

Figure 5-4.—Chipless cutter.

After the tubing is cut, remove all burrs and

sharp edges from inside and outside of the tube

(fig. 5-5) with deburring tools. Clean out the

tubing. Make sure no foreign particles remain.

A convenient method for cutting tubing with

a hacksaw is to place the tube in a flaring block

and clamp the block in a vice. After cutting the

tubing with a hacksaw, remove all saw marks by

filing.

Tube Bending

The objective in tube bending is to obtain a

smooth bend without flattening the tube. Tube

bending is usually done with either a hand tube

bender or a mechanically operated bender.

Figure 5-5.—Properly burred tubing.

5-5