Technical Directive for Piping Devices and

Flexible Hose Assemblies, NAVSEA S6430-AE-

TED-010. volume 1. provide detailed instructions

on discarding and downgrading of rubber hoses

exceeding their shelf life.

PFTE

1Q89 or

the first

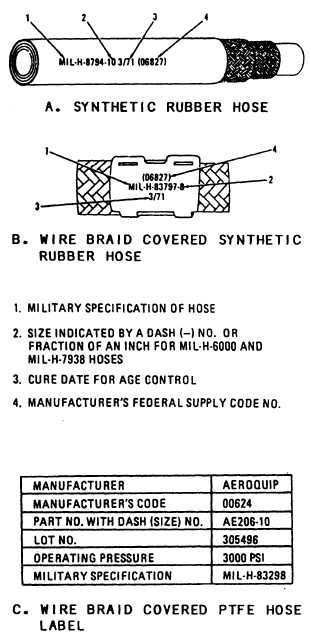

Figure 5-10.—Hose identification.

1/89 means the hose was made during

quarter (1 Jan to 31 Mar) of 1989.

The cure date limits the length of time a rubber

hose can be stored, in bulk or as an assembly,

prior to being placed into service. The storage or

shelf life for rubber hose is 4 years. For the hose

manufactured in 1Q89, the storage or shelf life

will end on the 31st of March 1993. At this point,

the hose is no longer considered usable and should

be discarded or downgraded. The Aviation Hose

and Tube Manual, NAVAIR 01-1A-20, and the

5-9

PFTE hose is a flexible hose designed to meet

the requirements of higher operating pressures and

temperatures in present fluid power systems. This

type of hose is made from a chemical resin, which

is processed and extruded into a tube shaped to

a desired size. It is reinforced with one or more

layers of braided stainless-steel wire or with an

even number of spiral wrap layers with an outer

wire braid layer.

PTFE hose is unaffected by all fluids presently

used in fluid power systems. It is inert to acids,

both concentrated and diluted. Certain PFTE

hose may be used in systems where operating

temperatures range from –100°F to +500°F.

PTFE is nonflammable; however, where the

possibility of open flame exists, a special asbestos

fire sleeve should be used.

PFTE hose will not absorb moisture. This,

together with its chemical inertness and anti-

adhesive characteristics, makes it ideal for missile

fluid power systems where noncontamination and

cleanliness are essential.

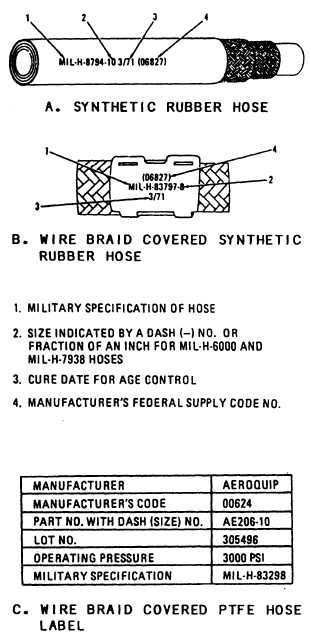

In lieu of layline marking, PTFE hoses are

identified by metal or pliable plastic bands at their

ends and at intervals along their length. Figure

5-10, view C, shows a hose label for a PTFE hose.

Usually the only condition that will shorten the

life of PTFE hose is excessive temperature. For

this reason there is no manufacture date listed on

the identification tag.

APPLICATION

As mentioned earlier, flexible hose is available

in three pressure ranges: low, medium, and high.

When replacing hoses, it is important to ensure

that the replacement hose is a duplicate of the one

removed in length, OD, material, type and

contour, and associated markings. In selecting

hose, several precautions must be observed. The

selected hose must

1.

2.

be compatible with the system fluid,

have a rated pressure greater than the design

pressure of the system,