a clamp to lock the end of the tubing inside the

die block, and a yoke with a compressor screw

and cone that slips over the die block and forms

the 45-degree flare on the end of the tube. The

screw has a T-handle. A double flaring tube has

adaptors that turn in the edge of the tube before

a regular 45-degree double flare is made.

To use the single flaring tool, first check to

see that the end of the tubing has been cut off

squarely and has had the burrs removed from

both inside and outside. Slip the flare nut onto

the tube before you make the flare. Then, open

the die block. Insert the end of the tubing into

the hole corresponding to the OD of the tubing

so that the end protrudes slightly above the top

face of the die blocks. The amount by which the

tubing extends above the blocks determines the

finished diameter of the flare. The flare must be

large enough to seat properly against the fitting,

but small enough that the threads of the flare nut

will slide over it. Close the die block and secure

the tool with the wing nut. Use the handle of the

yoke to tighten the wing nut. Then place the yoke

over the end of the tubing and tighten the handle

to force the cone into the end of the tubing. The

completed flare should be slightly visible above

the face of the die blocks.

FLEXIBLE HOSE

Shock-resistant, flexible hose assemblies are

required to absorb the movements of mounted

equipment under both normal operating condi-

tions and extreme conditions. They are also

used for their noise-attenuating properties and

to connect moving parts of certain equipment.

The two basic hose types are synthetic rubber

and polytetrafluoroethylene (PTFE), such as

Du Pont’s Teflon®fluorocarbon

resin.

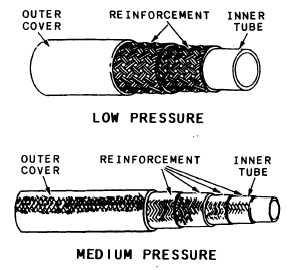

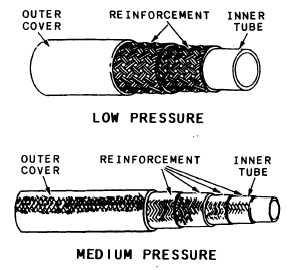

Figure 5-9.—Synthetic rubber hoses.

pressure ranges: low, medium, and high. The

outer cover is designed to withstand external abuse

and contains identification markings.

Synthetic rubber hoses with rubber covers are

identified with the military specification number,

the size by dash number, the quarter and year of

cure or manufacture, and the manufacturer’s code

identification number or federal supply code

number printed along their layline (fig. 5-10, view

A). The layline is a legible marking parallel to the

longitudinal axis of a hose used in determining

the straightness or lay of the hose.

Synthetic rubber hoses with wire braid cover

are identified by bands (fig. 5-10, view B) wrapped

around the hose ends and at intervals along the

length of the hose.

Sizing

Rubber hoses are designed for specific fluid,

temperature,

and pressure ranges and are

provided in various specifications. Rubber hoses

(fig. 5-9) consist of a minimum three layers; a

seamless synthetic rubber tube reinforced with one

or more layers of braided or spiraled cotton, wire,

or synthetic fiber; and an outer cover. The inner

tube is designed to withstand the attack of the

fluid that passes through it. The braided or

spiraled layers determine the strength of the hose.

The greater the number of these layers, the greater

is the pressure rating. Hoses are provided in three

5-8

The size of a flexible hose is identified by the

dash (-) number, which is the ID of the hose

expressed in 16ths of an inch. For example, the

ID of a -64 hose is 4 inches. For a few hose styles

this is the nominal and not the true ID.

Cure Date

Synthetic rubber hoses will deteriorate from

aging. A cure date is used to ensure that they do

not deteriorate beyond material and performance

specifications. The cure date is the quarter and

year the hose was manufactured. For example,