manner. Another reason for not leaving globe

valves in the fully open position is that it is

sometimes difficult to determine if the valve is

open or closed. If the valve is jammed in the open

position, the stem may be damaged or broken by

someone who thinks the valve is closed, and

attempts to open it.

It is important that globe valves be installed

with the pressure against the face of the disk to

keep the system pressure away from the stem

packing when the valve is shut.

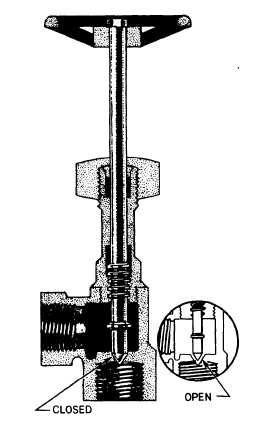

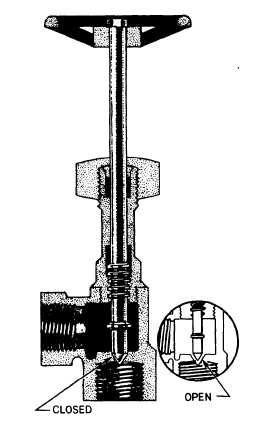

NEEDLE VALVES

Needle valves are similar in design and

operation to the globe valve. Instead of a disk,

a needle valve has a long tapered point at the end

of the valve stem. A cross-sectional view of a

needle valve is illustrated in figure 6-8.

The long taper of the valve element permits

a much smaller seating surface area than that of

the globe valve; therefore, the needle valve is more

suitable as a throttle valve. Needle valves are used

to control flow into delicate gauges, which

might be damaged by sudden surges of fluid under

pressure. Needle valves are also used to control

the end of a work cycle, where it is desirable for

motion to be brought slowly to a halt, and at other

points where precise adjustments of flow are

necessary and where a small rate of flow is

desired.

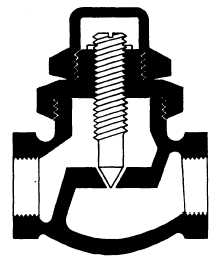

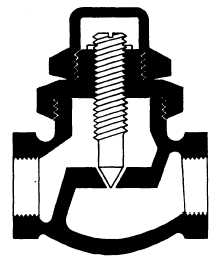

Although many of the needle valves used in

fluid power systems are the manually operated

type (fig. 6-8), modifications of this type of valve

are often used as variable restrictors. This valve is

constructed without a handwheel and is adjusted

to provide a specific rate of flow. This rate of flow

will provide a desired time of operation for a

particular subsystem. Since this type of valve can

be adjusted to conform to the requirements of a

particular system, it can be used in a variety of

systems. Figure 6-9 illustrates a needle valve that

was modified as a variable restrictor.

HYDRAULIC AND PNEUMATIC

GLOBE VALVES

The valve consists of a valve body and a stem

cartridge assembly. The stem cartridge assembly

includes the bonnet, gland nut, packing, packing

retainer, handle, stem, and seat. On small valves

(1/8 and 1/4 inch) the stem is made in one piece,

but on larger sizes it is made of a stem, guide,

and stem retainer. The valve disk is made of nylon

and is swaged into either the stem, for 1/8- and

1/4-inch valves, or the guide, for larger valves.

The bonnet screws into the valve body with

left-hand threads and is sealed by an O-ring

(including a back-up ring).

Figure 6-8.—Cross-sectional view of a needle valve.

Figure 6-9.—Variable restrictor.

6-5