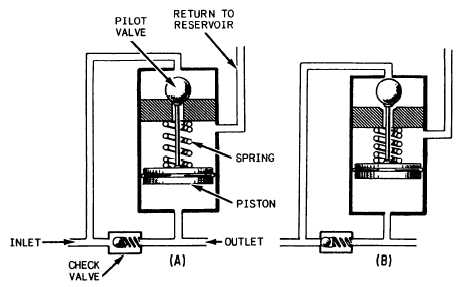

basic operating principles of all regulators are

similar to the one illustrated in figure 6-14.

A regulator is open when it is directing fluid

under pressure into the system (fig. 6-14, view A).

In the closed position (fig. 6-14, view B), the fluid

in the part of the system beyond the regulator is

trapped at the desired pressure, and the fluid from

the pump is bypassed into the return line and back

to the reservoir. To prevent constant opening and

closing (chatter), the regulator is designed to open

at a pressure somewhat lower than the closing

pressure. This difference is known as differential

or operating range. For example, assume that a

pressure regulator is set to open when the system

pressure drops below 600 psi, and close when the

pressure rises above 800 psi. The differential or

operating range is 200 psi.

Referring to figure 6-14, assume that the

piston has an area of 1 square inch, the pilot valve

has a cross-sectional area of one-fourth square

inch, and the piston spring provides 600 pounds

of force pushing the piston down. When the

pressure in the system is less than 600 psi, fluid

from the pump will enter the inlet port, flow to

the top of the regulator, and then to the pilot

valve. When the pressure of the fluid at the inlet

increases to the point where the force it creates

against the front of the check valve exceeds the

force created against the back of the check valve

by system pressure and the check valve spring, the

check valve opens. This allows fluid to flow into

the system and to the bottom of the regulator

against the piston. When the force created by the

system pressure exceeds the force exerted by the

spring, the piston moves up, causing the pilot

valve to unseat. Since the fluid will take the path

of least resistance, it will pass through the

regulator and back to the reservoir through the

return line.

When the fluid from the pump is suddenly

allowed a free path to return, the pressure on the

input side of the check valve drops and the check

valve closes. The fluid in the system is then

trapped under pressure. This fluid will remain

pressurized until a power unit is actuated, or until

pressure is slowly lost through normal internal

leakage within the system.

When the system pressure decreases to a point

slightly below 600 psi, the spring forces the piston

down and closes the pilot valve. When the pilot

valve is closed, the fluid cannot flow directly to

the return line. This causes the pressure to increase

in the line between the pump and the regulator.

This pressure opens the check valve, causing the

fluid to enter the system.

In summary, when the system pressure

decreases a certain amount, the pressure regulator

will open, sending fluid to the system. When the

system pressure increases sufficiently, the

regulator will close, allowing the fluid from the

pump to flow through the regulator and back to

the reservoir. The pressure regulator takes the load

off of the pump and regulates system pressure.

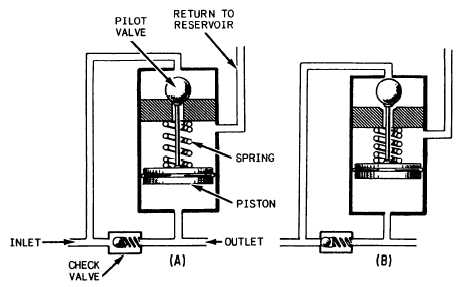

Figure 6-14.—Hydraulic pressure regulator.

6-10