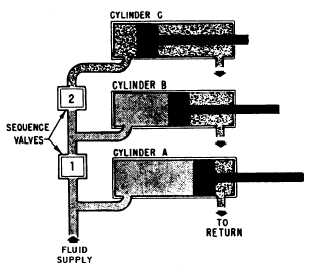

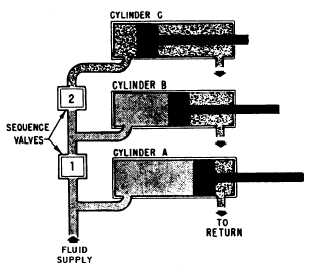

Figure 6-15.—Installation

SEQUENCE VALVES

of sequence valves.

Sequence valves control the sequence of

operation between two branches in a circuit; that

is, they enable one unit to automatically set

another unit into motion. An example of the use

of a sequence valve is in an aircraft landing gear

actuating system.

In a landing gear actuating system, the landing

gear doors must open before the landing gear

starts to extend. Conversely, the landing gear must

be completely retracted before the doors close. A

sequence valve installed in each landing gear

actuating line performs this function.

A sequence valve is somewhat similar to a

relief valve except that, after the set pressure has

been reached, the sequence valve diverts the fluid

to a second actuator or motor to do work in

another part of the system. Figure 6-15 shows an

installation of two sequence valves that control

the sequence of operation of three actuating

cylinders. Fluid is free to flow into cylinder A.

The first sequence valve (1) blocks the passage of

fluid until the piston in cylinder A moves to the

end of its stroke. At this time, sequence valve 1

opens, allowing fluid to enter cylinder B. This

action continues until all three pistons complete

their strokes.

There are various types of sequence valves.

Some are controlled by pressure and some are

controlled mechanically.

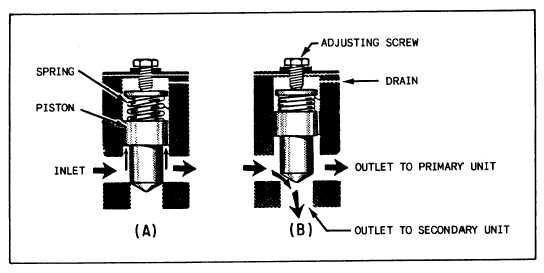

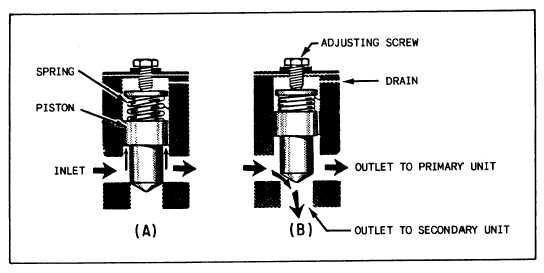

Pressure-Controlled Sequence Valve

The operation of a typical pressure-controlled

sequence valve is illustrated in figure 6-16. The

opening pressure is obtained by adjusting the

tension of the spring that normally holds the

piston in the closed position. (Note that the top

part of the piston has a larger diameter than the

lower part.) Fluid enters the valve through the

inlet port, flows around the lower part of the

piston and exits the outlet port, where it flows to

the primary (first) unit to be operated (fig. 6-16,

view A). This fluid pressure also acts against the

lower surface of the piston.

Figure 6-16.—Operation of a pressure-controlled sequence valve.

6-11