centers (fig, 4-1). External pumps may use spur

gears, herringbone gears, or helical gears to move

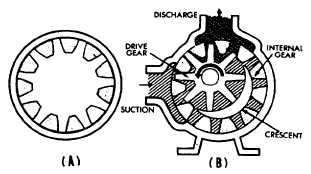

the fluid. In an internal gear pump, the teeth of

one gear project outward, but the teeth of the

other gear project inward toward the center of the

pump (fig. 4-2, view A). Internal gear pumps may

be either centered or off-centered.

Spur Gear Pump

The spur gear pump (fig. 4-1) consists of two

meshed gears which revolve in a housing. The

drive gear in the illustration is turned by a drive

shaft which is attached to the power source. The

clearances between the gear teeth as they mesh and

between the teeth and the pump housing are very

small.

The inlet port is connected to the fluid supply

line, and the outlet port is connected to the

pressure line. In figure 4-1 the drive gear is turning

in a counterclockwise direction, and the driven

(idle) gear is turning in a clockwise direction. As

Figure 4-2.—Off-centered internal gear pump.

the teeth pass the inlet port, liquid is trapped

between the teeth and the housing. This liquid is

carried around the housing to the outlet port. As

the teeth mesh again, the liquid between the teeth

is pushed into the outlet port. This action

produces a positive flow of liquid into the system.

A shearpin or shear section is incorporated in the

drive shaft. This is to protect the power source

Figure 4-1.—Gear-type rotary pump.

4-3