The amount of material required is known as the bend

allowance.

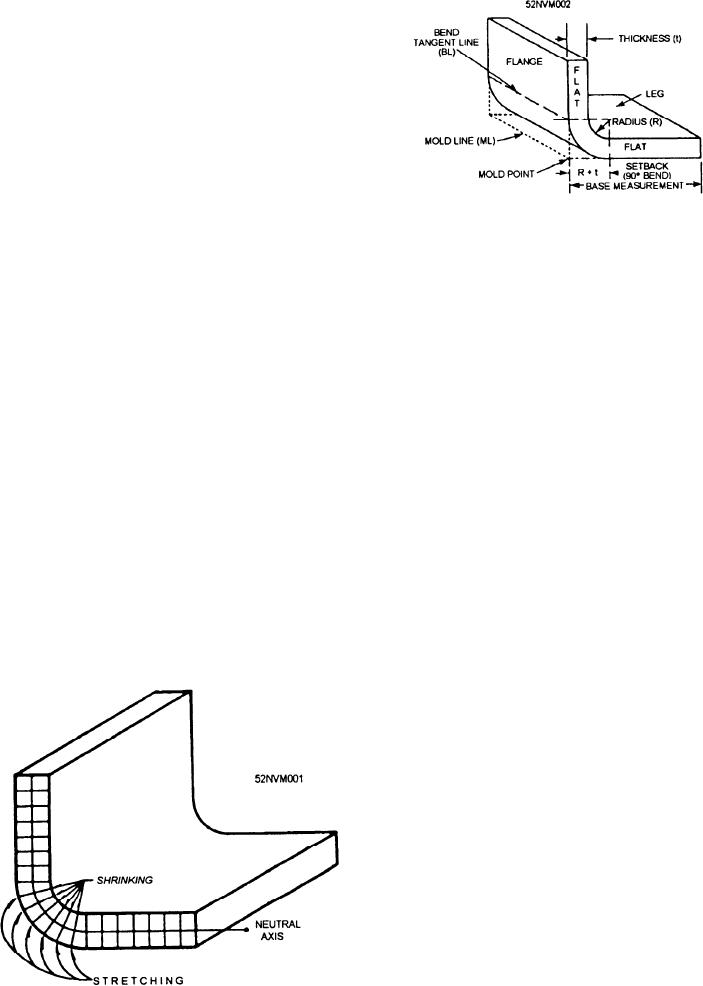

In bending, the metal is compressed on the inside

of the bend, and stretched on the outside of the bend.

Halfway between these two surfaces or extremes is a

space that neither shrinks nor stretches but retains the

same length. This is known as the neutral axis. Figure

13-47 shows the neutral axis of a bend. The bend

allowance is computed along this neutral axis.

Bend Allowance Terms

Figure 13-48.--Bend allowance terms.

To understand the calculation and discussion of

bend allowance, you need to be thoroughly familiar

RADIUS (R)--The radius of the bend. It is always

with the definitions used to calculate bend allowance.

measured from the inside of the bend unless

As you study the definitions, refer to figure 13-48 and

otherwise stated.

locate each part described. Some parts are not shown

SETBACK (SB)--The amount that the two mold

in the figure but are described in the text. This section

line dimensions overlap when they are bent around

may be difficult to understand. You may need to go over

the formed part. In a 90-degree bend, SB = R + t

it with a more experienced HT. The definitions are as

(radius of the bend plus thickness of the metal).

follows:

BEND LINE (also called brake or sight line)--The

LEG--The longer part of a formed angle.

layout line on the metal being formed which is set

FLANGE--The shorter part of a formed angle. If

even with the nose of the brake and serves as a guide

both parts are the same length, each is known as a

in bending the work. (Before forming a bend, you

leg.

must decide which end of the material can be most

conveniently inserted in the brake.) The bend line

MOLD LINE (ML)--The line formed by extending

the outside surfaces of the leg and flange so that

is then measured and marked off with a soft pencil.

they intersect.

Measure from the bend tangent line closest to the

end that is to be placed under the brake. This

BEND TANGENT LINE (BL)--The line at which

measurement should be equal to the radius of the

the metal starts to bend.

bend. The metal is then inserted in the brake so that

BEND ALLOWANCE (BA)--The amount of

the nose of the brake will fall directly over the bend

material consumed in making the bend.

line.

FLAT PORTION OR FLAT--The flat portion or

flat of a plate is that portion that is not included in

the bend. It is equal to the base measurements

minus the setback.

B A S E MEASUREMENT (or mold line

measurement)--The base measurement is the

outside dimensions of a formed plate. Base

measurement will either be given on the blueprint

or drawing, or it may be obtained from the original

part.

CLOSED ANGLE--An angle that is less than 90

when measured between legs, or more than 90

when the amount of bend is measured.

OPEN ANGLE--An angle that is more than 90

when measured between legs, or less than 90 when

the amount of bend is measured.

Figure 13-47.--Neutral axis.

13-41