difficult to carve, but when used for small patterns,

flat surface without full air circulation will usually

it will outlast pine 5 to 1.

warp toward the exposed surface. The air draws

more moisture from the exposed surface than from

the underneath surface.

LIGNUM VITAE is excessively heavy, hard, and

resinous. Its color varies from light yellow to dark

The carpenter shop usually has overhead lumber

greenish-brown--at times almost black. This wood

storage racks. The bulk of the lumber is stowed in

is native to tropical America, New South Wales, and

other parts of the ship because of space limitations

New Zealand.

aboard a repair ship or tender.

TEAK is heavy, strong, and oily. It has a dark

You should maintain a careful record of the

color. It does not shrink, crack, or warp. Teak

lumber used and on hand. If possible, at least 3

comes from East India.

months' supply should be on hand.

Care and Storage of Lumber

MANUFACTURED WOOD PRODUCTS

Lumber is a tool like the saw or plane and

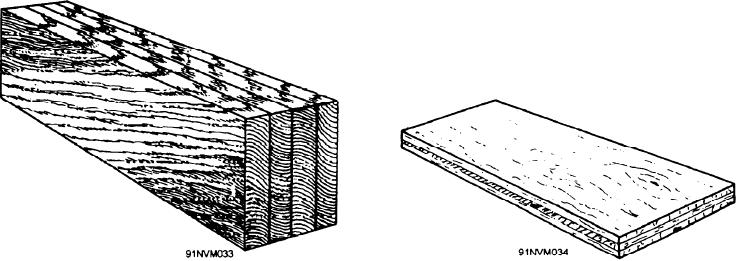

Laminated lumber is made up of layers of wood

should be considered as such. Store and care for

glued face-to-face (fig. 3-7). The parts glued

lumber properly. This will prevent it from becoming

together to make laminated lumber may be thinly

water-soaked, rotted, or warped. The best way to

sliced sheets of veneer or they may be sawed boards.

stow lumber is by stacking it on end in racks. This

way air can circulate around all the boards.

One advantage of laminated wood is that it can

Circulation dries the wood evenly and reduces

be any desired thickness. Also, staggering the ends

warping.

of individual layers can produce timbers that are

much longer than solid timbers.

Room for storing lumber on end is hard to find

aboard ship. Lumber usually gets stored in the next

Plywood (fig. 3-8) is thin layers of wood glued

best manner. The accepted method is to store the

face-to-face. It usually has the grain of each layer

lumber horizontally. Separate the lumber by sizes.

at right angles to the next layer. Plywood alternates

Put the l-inch lumber together, the 1 1/2-inch

grain each ply, and laminated wood never alternates

lumber together, and so on. When placing the

grain. Plywood always has an odd number of plies.

lumber in racks, you should place small strips or

Veneered stock for furniture manufacture usually

battens about 1 inch thick across the boards about

has five layers. A thick layer called the core is in

6 feet apart. This will separate the boards and form

the center. The layers that are glued on with the

a space for the air to circulate around them. Air

grain running across are called cross bands. The

circulation is important. A dressed board laid on its

surface layers or faces are placed so their grain runs

parallel to the length of the panel.

One-quarter inch and one-eighth inch fir

plywood has only 3 plies. Plywood always has an

odd number of plies--up to 15. The standard size of

Figure 3-8.--Plywood.

Figure 3-7.--Laminated lumber.

3-12