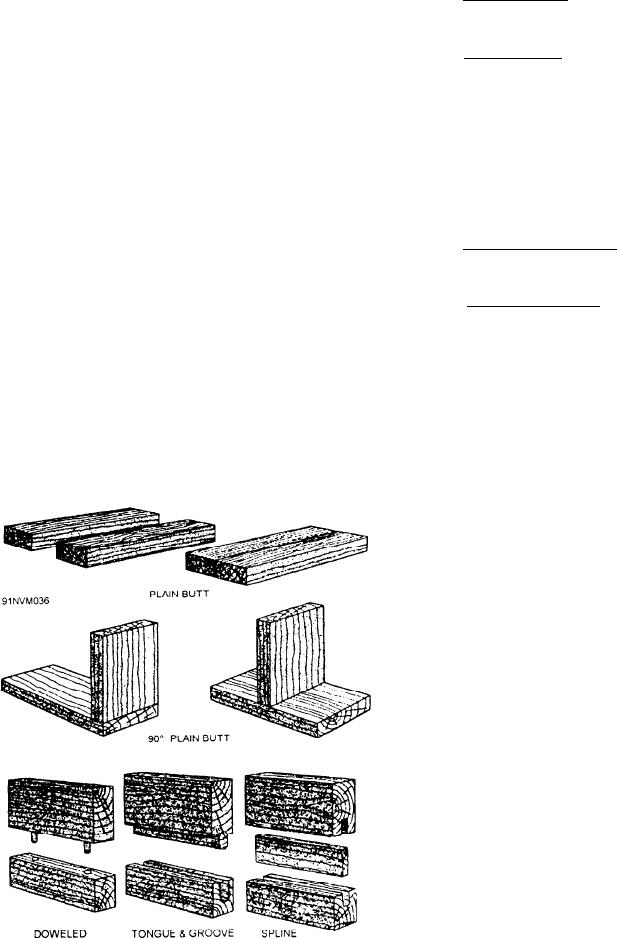

The plain butt joint is the simplest and the one

WOOD JOINERY

most used by the HT.

An important skill to master is wood joinery. In

The doweled joint is usually a plain butt joint

woodworking, joinery is the art of combining two or

that has been given greater strength with wooden

more pieces of material into one. The purpose for

dowels. Dowels also reinforce other joints such as

this procedure is to increase dimensions, strength, or

the miter and half lap.

material alignment. Wood joinery includes the

manufacture of wood joints and the various devices

When choosing a dowel for edge-to-edge use,

or methods used to fasten them together. These

the dowel diameter should be one-third the

methods include glue, screws, and brads.

thickness of the stock you are jointing. Thus,

3/4-inch thick stock would require a 1/4-inch dowel.

A joint is only as strong as its weakest point.

This can be the joints if they are incorrectly made or

The tongue-and-groove joint is stronger than the

if you use the wrong joint. Correct joint usage and

butt or dowel joint. It is used for wood flooring.

proper construction can make the joint the strongest

point of the project.

The splined edge joint is a variation of the

tongue-and-groove joint. It is easier to make

STANDARD JOINTS

because two matching grooves and a separate spline

replace the tongue. Minimal strength is gained if

There are four standard methods for joining

the grain direction of the spline is parallel to the

wood stock edge-to-edge. These methods are the

edges, as shown in figure 3-11. A significant

plain butt, dowel, tongue-and-groove, and splined

strength gain results when the grain direction of the

edge joints shown in figure 3-10.

spline is perpendicular to the edges.

The thickness of both the spline and tongue

should be one-third of the material thickness. The

width of the spline should be equal to twice the

material thickness, while the tongue width should be

the same as the thickness. For example, 3/4-inch

stock would require a spline measuring 1/4 inch

thick and 1 1/2 inches wide or a tongue measuring

1/4 inch thick and 3/4 inch wide (fig. 3-11).

Lap Joints

Lap joints are shown in figure 3-12. Plain lap

joints are used in all kinds of construction,

particularly if appearance is not a factor. The end

butt half lap is not as strong as the plain lap joint,

but it looks better and requires less space. The

corner half lap works well for framing buildings,

boxes, and cabinets. The cross lap joint joins the

spokes of a wheel pattern.

The scarf joint (fig. 3-13) is a special type of lap

joint that is used to join heavy timbers. For repair

purposes, the recommended slope is 1 in 12. The

cut should slant through the length of a piece of

wood 12 inches for every inch of depth or width.

The end butt joint with fishplates (fig. 3-14) is

useful for joining short members to make long

Figure 3-10.--Edge joints.

pieces. Secure the fishplates with nails, screws,

3-14