plywood sheets is 4 feet wide by 8 feet long, though

fiber faces that provide better painting surfaces and

smaller and larger sizes are available. Because of

better wearing qualities.

the cross-grain effect, splitting plywood is very

difficult and shrinking and swelling are rare.

Because of the conditions of its manufacture,

plywood is dry when received. It should be stored

in a closed shed. For long storage, a heated storage

The development of special glues and bonding

area is recommended.

materials has made plywood highly resistant to

water. It was widely used during World War II and

is still in use in the Navy.

Plywood is commonly stacked in solid piles.

Under humid conditions, edges swell because of

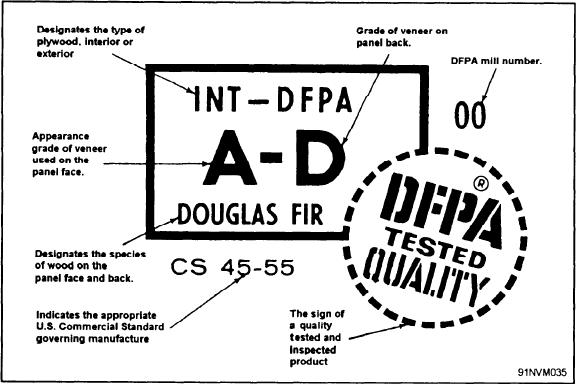

Two basic grades of plywood are interior and

exposed end grain. This swelling causes dishing,

exterior. Interior plywood is unreliable in wet

especially in the upper panels of high piles. Reduce

places. Exterior plywood will keep its original form

dishing by placing strips between sheets of stacked

and strength when subjected to the elements. It is

plywood. Use enough strips to prevent the plywood

suitable for permanent exterior use provided it is

from sagging between strips. Dry l-inch strips are

properly protected from the elements.

Most

suitable for supporting plywood.

plywood is branded or stamped on the edge with the

symbol EXT. or INT. More complete information

Hardboard is known by several trade names. It

is stamped on the back of the plywood sheet. A

is wood fibers separated, treated, and then subjected

typical Douglas fir back stamp, with all symbols

to heat and heavy pressure. Hardboard is available

explained, is shown in figure 3-9.

in thicknesses from 1/16 inch to 5/6 inch. The most

common size is 4-foot by 8-foot sheets, but other

Plywood is graded by the quality of the face

sizes are available. Hardboard comes in a plain,

veneers. Grade A is the best. Grade D is the

smooth surface or in several glossy finishes. Some

poorest (fig. 3-9). Grading is based upon the

finishes imitate tile or stone. Use class B treated

number of defects, such as knotholes, pitch pockets,

hardboard where moisture resistance or strength is

and splits. It also considers the presence of streaks,

r e q u i r e d . Otherwise, class A hardboard is

discolorations, sapwood, shims, and patches in the

satisfactory.

face of the panel. Plywood has resin-impregnated

Figure 3-9.--Typical Douglas fir back stamp.

3-13