dangerous equipment found in R-l division. All

structural shops, regardless of the type of ship or shore

facility you will be assigned to, have some or all of the

equipment discussed in this chapter. It is important that

you have a general understanding and knowledge of

how to use these different types of equipment. It is not

the intent of this training manual to make you an expert

on the use and operation of the different machines. You

should, however, be able to identify the types of

machinery, the general operation, and safety

precautions associated with this equipment.

The machinery found in most structural shops can

be classified into two basic categories: cutting

machines and forming machines.

CUTTING MACHINERY

This section will take a look at machinery

associated with cutting metal plate and shapes. You

have already studied some of the equipment associated

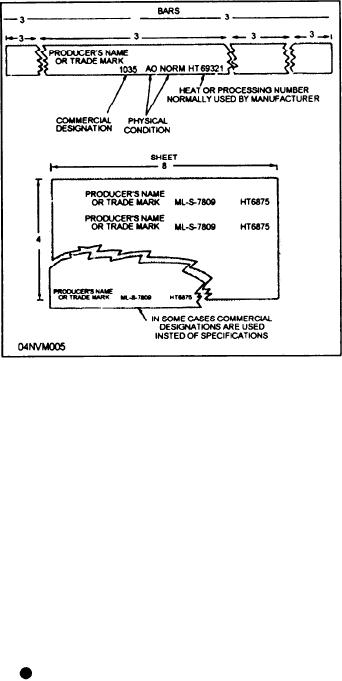

Figure 13-20.--Examples of continuous identification

with cutting plate, such as the oxyacetylene torch,

marking.

mechanical hacksaw, and band saws that are found in

some of the smaller shops in the fleet. This section will

society or industrial association. Some of the

include such machinery as the shear, universal

designations used are as follows:

ironworker, Pullmax, and plasma arc machine.

CR--Cold rolled

Drop Shear

HR--Hot rolled

The drop shear enables the HT to produce quality

HT--Heat treated

work in minimum time. The drop shear is used to trim

AQ--Aircraft quality

metal and make straight cuts with square sides. Metal,

such as mild steel, black iron, copper, aluminum, and

1/4H--Quarter hard

stainless steel, can be cut on the drop shear.

HTQ--High tensile quality

You have already been introduced to the squaring

shear in chapter 12 of this text. The drop shear is very

Specification data, such as the revision letter of

similar to the squaring shear but the drop shear is

the specification number, type, grade, class of

designed to cut thick plates. Most drop shears on ships

material or manufacturer's specification data,

and at shore facilities are designed to cut plate from l/8

such as heat number.

to l/2 inch thick. Metal thinner than l/8 inch should be

Small metal shapes, such as small tubing, coils of

cut on a squaring shear in the sheet metal shop since the

wire, and bar stock, cannot be marked readily by this

drop shear would just bend the sheet metal around the

method. On these items, the material may be tagged.

knives. Drop shears at some shipyards are designed to

Whenever a piece of material is removed from the

cut plate 1 inch and thicker.

original piece, you should mark the piece if the marking

SHEAR SAFETY.--As with any job or

label is incomplete or destroyed. This will prevent the

equipment, safety should be your primary concern. The

piece from being mistaken for another type of material

drop shear is a very dangerous piece of equipment to

or from being used where it shouldn't be used.

operate due to the force required to cut thick metal. As

you can imagine, it requires a lot of shearing force to

SHIPFITTER SHOP EQUIPMENT

cut thick plate. To compound this danger, the shearing

force is accomplished in one stroke of the machine.

Shipfitter shops, whether ashore are afloat, are

Once you have tripped the release lever, the shearing

equipped with some of the largest, most powerful, and

action is nonstoppable until the machine has made one

13-19