--Never, never have your foot on the trip lever or

complete revolution. If you accidently trip the release

pedal while loading or adjusting plate on the shear.

lever, whatever is beneath the knives will be cut,

Numerous accidents have occurred because of the shear

including fingers.

being accidentally tripped.

The following is a list of some of the more common

--Never cut pipe, bar stock, round stock, flat bar

safety precautions:

less than 2 inches in width or other similar metal shapes.

--Become familiar with the type of drop shear

If you attempt to shear these types of metal shapes, you

will damage the cutting knives and risk injury due the

installed in your shop. Qualify on its use and operation

met al flying out from the holddown dogs, since the dogs

under qualified supervision prior to operating the shear.

are designed for flat plate.

--Determine the capacity of the machine being

SHEAR NOMENCLATURE.--As with any

used from the manufacturer's technical manual and

piece of equipment, you should have an understanding

NEVER exceed its maximum capacity. Capacities for

of the major parts of the equipment and their function.

most machines are given in metal thickness, and length,

Figure 13-2 1 illustrates some of the parts common to all

and, unless otherwise noted, are given for mild steel not

drop shears. These parts arc listed as follows:

alloy steels. As metal hardness increases, machine

capacity decreases.

The finger guard is located on the front of the

machine and is designed to prevent your

--Never place any part of your body under the

fingers from king cut.

knives or dogs (holddowns) of the shear.

--Never place hands or fingers between the metal

Holddowns (dogs) are located behind the

plate and the bed.

linger guard and arc designed to automatically

--Ensure that the metal plate is under a holddown

operate when the release lever is tripped.

These dogs clamp the plate in place with

dog.

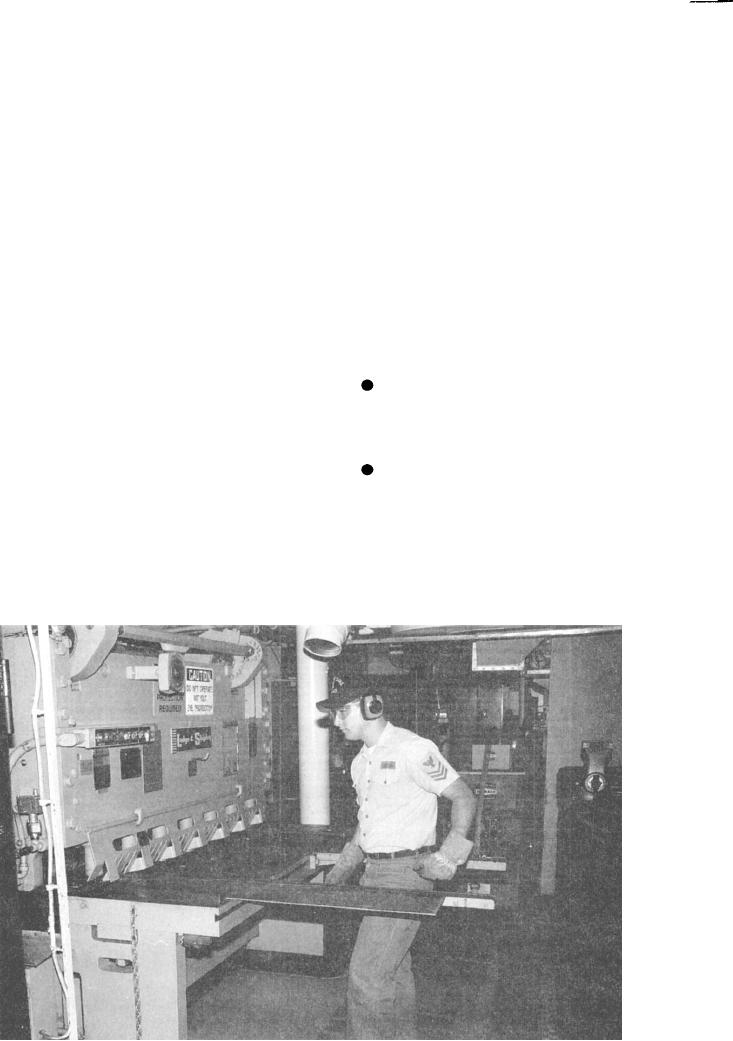

Figure 13-21.--Common drop shear.

13-20