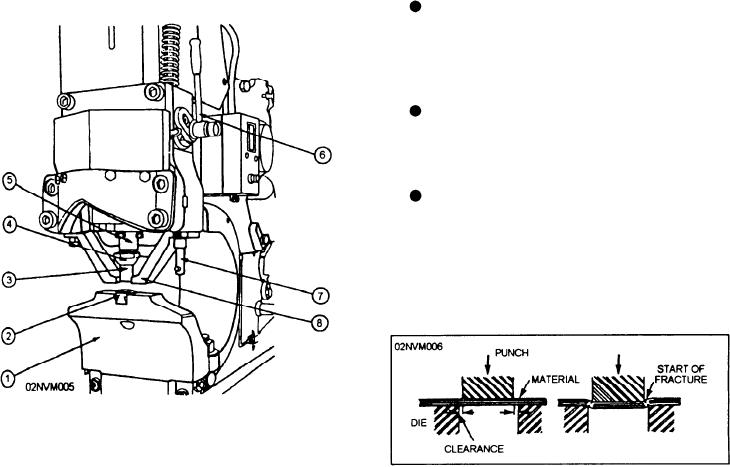

--Select the appropriate die, depending on the

--Make no modifications that will speed up or

punch-to-die clearance. Figure 13-26 shows the

continually cycle machine.

punch-to-die clearance. The punch-to-die clearance is

PUNCHING OPERATIONS.--The punch end of

the distance between the outer circumference of the

the universal ironworker punches rounds, squares, and

punch and the inner circumference of the die, when the

oblongs. The deep punch throat allows punching to the

punch sits in the die.

center of wide plates. The standard universal die block

--The punch diameter must be the same thickness

permits punching a full range of angles, beams, and

or greater than the plate thickness being punched.

channels.

--The punch-to-die clearance for mild steel with a

Punch Head.--The main part of the punching

thickness of l/4 inch through 5/8 inch should be l/32

device is a punch head. In the older machines, the

inch.

punch head is referred to as a full-floating head since

the dieblock is adjustable to allow the alignment of the

--The punch-to-die clearance for 3/4-inch mild

die to the punch. In the newer machines, the dieblock

steel should be l/16 inch.

is stationary while the die is adjusted for alignment with

--For metal less than l/4 inch, the recommended

the punch. The major components of the punch end are

punch-to-die clearance is l/10 of the thickness of the

as follows (fig. 13-25).

material.

Punch and Die Selection.--On the punch end, the

--The punch-to-die ratio should never be less than

punch to die selection is the utmost importance. Select

0.010 inch due to working clearances necessary in the

the proper size and shape of the punch and die according

punch head.

to the type and thickness of material to be punched.

Operating Procedure. --To operate the punch,

Refer to the manufacturer's manual for standard tooling

refer to figure 13-25 and proceed according to the

sizes. You should keep the following points in mind

following precautions and steps:

when selecting punches and dies.

Install the punch and die and check the

alignment and adjust as necessary. Ensure that

the punch passes through the die without

striking the shoulders of the die.

Cycle the machine through one complete

revolution checking the machine for binding or

misalignment.

Place the workpiece under the punch and

"spot" the punch to the workpiece. This may

be accomplished by using the hand lever in the

older mechanical machines or by the jog button

on the hydraulic machines.

1.

Dieblock

5.

Punch Holder

6.

Hand Lever

2.

Die

7.

Stripper ACS Lever

3.

Punch

8.

Stripper

4.

Coupling Nut

Figure 13-26.--Punch-to-die clearance.

Figure 13-25.--Punch floating head.

13-24