capacity will be reduced. The cutting and shaping

of this machine, you should study the operator's manual

and practice on the machine in your shop, if it has one

action is provided by tools mounted in tool holders at

installed.

the front of the machine. The machine has two speeds

of operation: slow and fast.

PULLMAX SAFETY.--The Pullmax is a

relatively simple machine to operate and does not

When the motor is running at slow speed, the

present any special safety requirements. However, you

cutting tool makes 500 to 1,000 strokes per minute.

need to ensure that the tooling is installed correctly. The

Slow speed is used to cut heavy gauge metal.

machine cuts using a reciprocating action that causes

abnormal vibration in the workpiece. Therefore, do not

When the motor is running at high speed, the cutting

operate the machine for extended periods of time

tool makes 1,000 to 2,000 strokes per minute. High

without taking a break from machine operations. You

speed is used to cut thin gauge metal.

can seriously damage your hands and arms by exposing

PULLMAX OPERATIONS.--The Pullmax has

them to continuous vibration.

the capacity to perform many specific operations

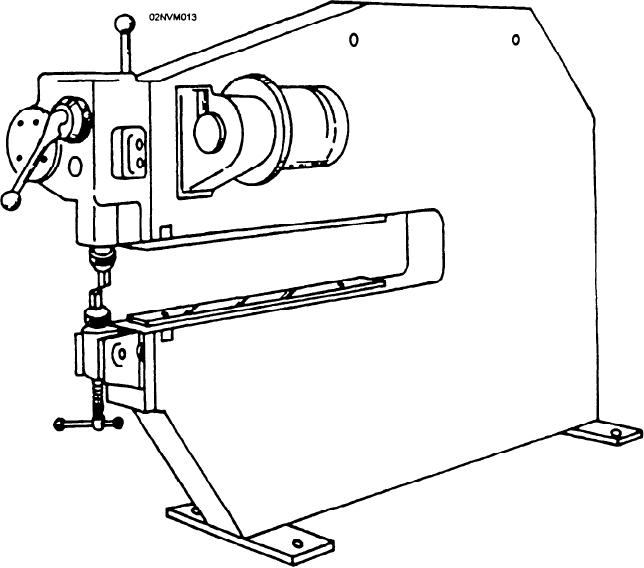

GENERAL SPECIFICATIONS.--Most

depending on the tools (blades) installed in the machine.

shipfitter shops are equipped with machines capable of

Figures 13-35 and 13-36 show two of several different

cutting plate up to 3/8 inch thick, as shown in figure

tools made for the Pullmax. We will be discussing the

13-33. As in all machines, the thickness capacity is

tools used for shearing (cutting) (fig. 13-34).

given for mild steel. If using alloy steel, the thickness

Figure 13-33.--Universal Pullmax machine.

13-28