tool so that it will only penetrate 1/3 of the thickness

being cut.

7. Cycle the machine, checking the machine for

binding or misalignment.

8. Make a test cut on a sample of the metal being

cut.

Stroke and Speed Control.--The stroke and speed

of the upper tool is important if a smooth cut is to be

obtained. We have already discussed speed control

earlier. You should remember that high speed is used

to cut thin metal and slow speed is used to cut thicker

gauge metal Stroke control is obtained by using the

same lever that lowers the upper tool into the cutting

position. When the lever is engaged to the left, you will

get a short stroke. A short stroke is used to cut thin

metal. When the lever is engaged to the right, you will

get a long stroke, which is used to cut thin metal.

Plasma Arc Machine

Plasma arc cutting is a high-speed, high-quality

metal cutting process that greatly reduces cutting and

edge preparation costs. Plasma arc cutting is similar to

tungsten inert gas welding because it uses the same

basic circuit and shielding gas. The plasma arc cutting

torch greatly reduces cutting time and replaces slower

machinery previously used to accomplish the same task.

The cutting process uses extremely high temperatures,

high-velocity ions, and a constricted arc between a

tungsten electrode and the piece to be cut. This section

will describe the procedures for using a typical thermal

arc cutting system with water cooling at 300 amperes.

PLASMA ARC CUTTING SAFETY.--Plasma

arc cutting requires the same personal protection

equipment that is required for arc welding. Plasma arc

cutting produces toxic gases from the cutting process.

It also produces hot sparks and sound levels above 105

decibels. It uses higher temperatures than arc welding.

You should never use solvents and degreasers of the

halogen family near the cutting operation, because light

from the arc can break these down into toxic

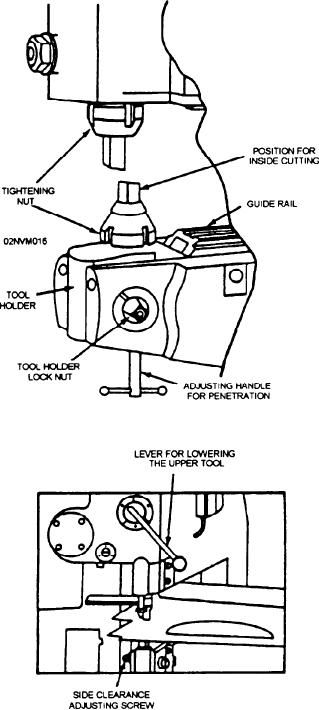

Figure 13-36.--Pullmax universal machine, upper and lower

components. The halogen family includes any of the

cutting tools.

nonmetallic elements, such as fluorine, chlorine, iodine,

bromine, and astatine.

5. When the adjustment is correct, tighten the

PLASMA ARC EQUIPMENT.--The equipment

used for plasma arc cutting is similar to a gas tungsten

toolholder locknut opposite the adjusting screw.

arc welding (GTAW) unit. The plasma arc cutting unit

6. Make adjustments for proper penetration with

has four basic components: the control panel, torch,

the tools in the cutting position. Use the adjusting

torch leads, and gas supply. Figure 13-37 shows a

handle at the bottom of the toolholder to adjust the lower

typical setup for the control panel and torch.

13-30