FORMING MACHINERY

gases are used for the plasma gas in cutting aluminum,

and nitrogen(N) is used for other metals. The shielding

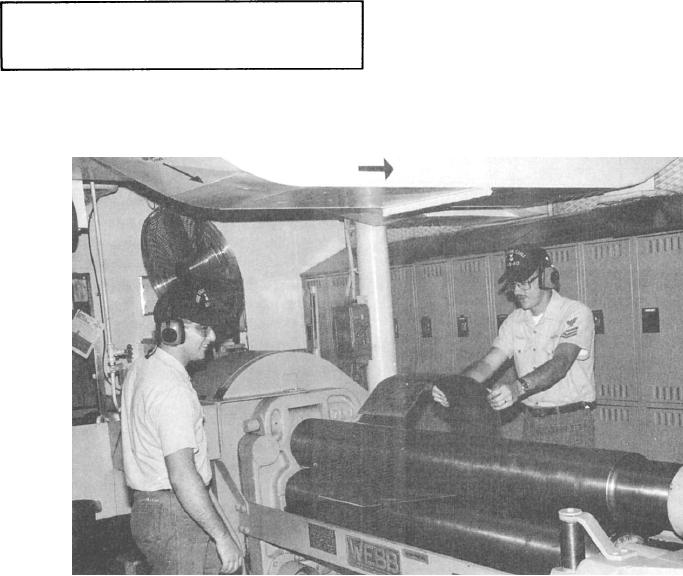

This section will take a look at machinery

gas used is carbon dioxide (CO2). Table 13-4 shows the

associated with forming metal plate and shapes, such as

gas mixtures for automatic and manual cutting process.

the sliproll forming machine, the brake press, and the

PLASMA ARC CUTTING PROCESS.--The

Hossfeld Bender.

plasma arc cutting process employs extremely high

temperatures, high-velocity ions, and a constricted arc

Sliproll Forming Machine

between a tungsten electrode and the piece to be cut.

This concentrated and columnated energy is produced

Sheet metal can be formed into curves over pipe or

by the electrode heating the plasma gas in the torch body

a mandrel, but steel plate requires machinery capable of

to produce high-temperature ionized gas. This ionized

providing considerably more pressure in the forming

gas is forced out of the torch through the ceramic cup,

process. You have already been introduced to the

which concentrates and colmunates the energy. As the

sliproll forming machine in the chapter 12. The

ionized gas strikes the plate, the metal is melted and the

powered sliproll machine (fig. 13-38) used in the

jet-like action of the arc removes the molten metal

shipfitter shop operates on the same principle as the

mechanically. The inert gas atmosphere prevents

hand-powered sliproll used in the sheet metal shop. The

oxidation of the kerf wall.

powered sliproll machines found in the shipfitter shop

are capable of rolling plate up to l/2 inch in thickness.

Table 13-4.--Gas Mixtures for Plasma Arc Cutting Machines

Since steel plate is stiffer than sheet metal, you must

take greater care when feeding the plate into the

(Aluminum)

40 psi

Plasma Gas AR/H2

machine to ensure accurate rolling of the plate. Figure

Plasma Gas N2

(All others)

20 - 40 psi

13-39 shows some of the common problems associated

40 psi

Secondary Gas CO2

with rolling plate.

Figure 13-38.--Sliproll forming machine.

13-32