--Never, never have your foot on the trip lever or

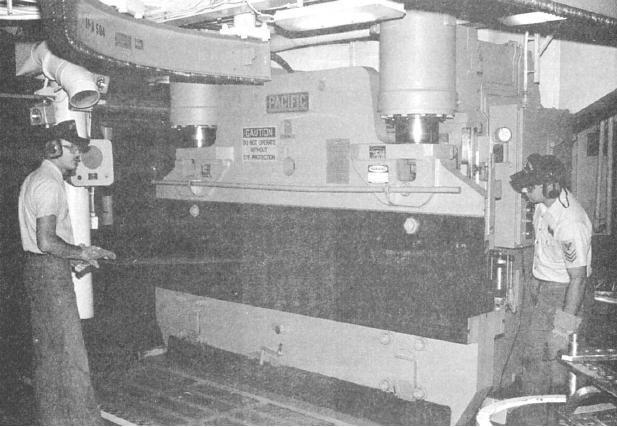

setup, and operation of a typical brake press. Figure

foot pedal while loading or adjusting plate on the

13-40 shows a typical brake press.

brake.

BRAKE PRESS SAFETY.--The brake press is

--Never attempt to bend pipe, bar stock, round

capable of operating at hydraulic pressures of up to 300

stock, flat bar less than 2 inches in width, or other

tons. Due to these high pressures and the machine

similar metal shapes. If you attempt to bend these types

operating capacity, there are several important safety

of metal shapes, you will damage the dies and risk

precautions you should follow. They are as follows:

injury.

--Become familiar with the type of brake press

BRAKE PRESS SETUP.--When you set up the

installed in your shop. Qualify on its use and operation

brake press, there are three important setup adjustments

under qualified supervision prior to operating the brake

to make. You must select the proper set of dies, bending

press.

pressure, and machine stroke. We will look at the

requirements for each of these adjustments.

--Determine the capacity of the machine being

used from the manufacturer's technical manual and

Die Selection.--The brake press is capable of using

NEVER exceed its maximum capacity. Capacities for

different dies to perform several different functions.

most machines are given in metal thickness, length, and,

The top half of the die is called the punch and the lower

half is called the die. The "V" die is the most common

unless otherwise noted, are given for mild steel not alloy

punch and die combination used in the shipfitter shop.

steels.

These dies allow plate to be bent at various angles.

--Never place any part of your body under the dies

When selecting the opening for the "V" die, it should

and punches of the press brake.

equal eight times the thickness of plate being bent. You

--Never place hands or fingers between the metal

will find a single "V" die with four openings in most

shipfitter shops for bending l/8-, l/4-, 3/8-, and

plate and the die.

Figure 13-40.--Brake press.

13-34