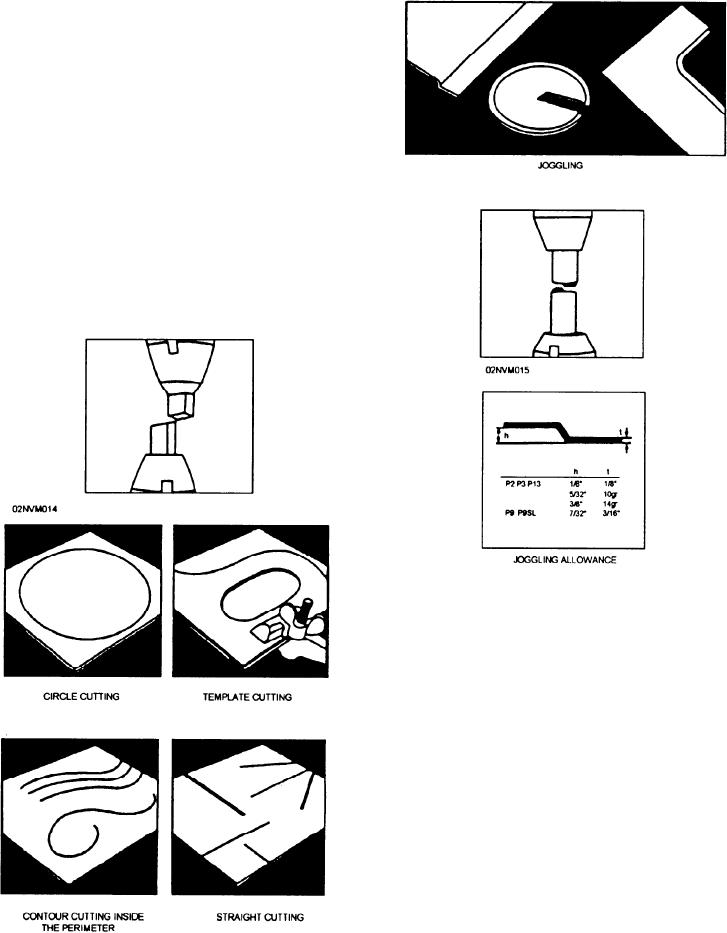

Tooling Setup.--Select the proper tooling for the

task assigned. For cutting straight and circular lines,

use shearing tools, as shown in figure 13-36. Shearing

tools may be used for cutting a freehand pattern or for

contouring the inside or outside perimeter of a project.

Tooling setup steps are as follows:

1. Select the proper tooling and install them in

the proper tool holder. Hand tighten the tightening

nut. Figure 13-36 shows the proper positioning of the

tools.

2. Lower the upper tool into the cutting position by

using the lever on the front of the machine, as shown in

figure 13-36.

Figure 13-35.--Joggling tools.

3. With the tools in the cutting position, check the

clearance between the upper and lower tooling. Use a

piece of white paper as a background to check for side

clearance. Look from one side directly at the white

paper background. You should have a clearance of

0.002 to 0.003 inch. An improper clearance adjustment

will result in a poor quality cut or damage to the

machine.

4. Adjust the tool for side clearance by turning

the side adjustment screw located on the left-hand

side of the toolholder, as shown in figure 13-36.

Turning the adjustment screw clockwise will close

the clearance; while turning it counterclockwise

will open the clearance between the tools.

Figure 13-34.--Shearing tools.

13-29