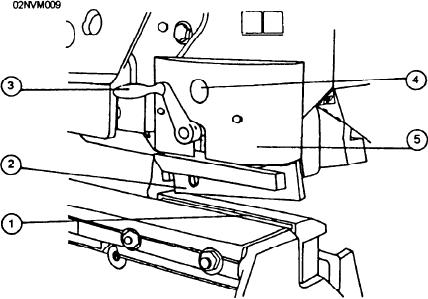

4. Grease Fitting

1. Stationary Blade

5. Holddown

2. Shear Blades

3. Holddown Adjusting Crank

Figure 13-29.--Universal ironworker shear end.

and at the same station on other machines. Regardless

Knife Clearances.--There are two sets of knife

of the physical arrangement of the machine, a punch and

clearances for the stock cutting stations. For the bar

die are used to perform the cutting action. The notcher

cutter station (fig. 13-28), the proper knife clearance is

makes angle cuts of 90 degrees to permit the bending of

0.006 inch. The shearing station has a clearance of

angle shapes. The coper makes partial rectangularcuts

0.002 inch to 0.003 inch. If shimming is required to

into metal stock. On some machines the coper punch is

maintain clearances, always shim the stationary knife,

never the plunger (moveable) knife.

also designed for notching. Figure 13-30 shows some

of the typical notching and coping work and figures

Operating Procedure.--To operate the bar cutting

13-31 and 13-32 show the notching and coping

stations, proceed according to the following precautions

stations.

and steps:

Knife Clearances.--There are two sets of

1 .Check the alignment and clearances of the

knife clearances for the notching and coping

cutting knives and adjust as necessary. Ensure that the

stations if they are separate stations. If the stations

knives are firmly fastened since they have a tendency

are combined, there will only be one set of

to work loose during use.

clearances. For the coping station (fig. 13-32) the

2. Cycle the machine through one complete

proper knife clearance is l/16 inch. The notching

revolution to check the machine for binding or

station (fig. 13-31) has a clearance of l/64 inch. If

misalignment.

shimming is required to maintain clearances,

always shim the stationary knife, never the plunger

3. Place the workpiece between the cutting knives

(moveable) knife. On combined stations, the knife

and adjust the holddowns to support the material being

clearance is l/l6 inch.

cut and prevent kickup.

Operating Procedure.--To operate the notching

4. Step on the foot pedal and hold the pressure until

and coping stations, proceed according to the following

the knives have cut the workpiece.

precautions and steps:

COPING AND NOTCHING OPERA-

1. Check the alignment and clearances of the

TIONS.--Coping and notching operations are

cutting knives and adjust as necessary. Ensure that the

performed at individual stations on some machines

13-26