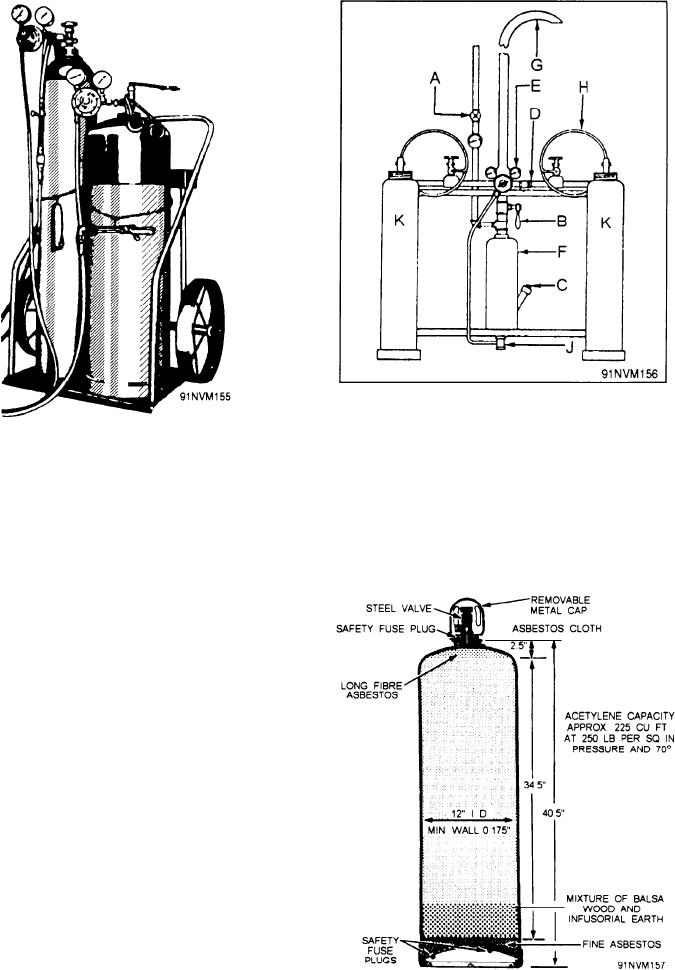

F. Flash arrester chamber

A.

Line valve

G. Escape pipe

B.

Release valve

C.

Filler plug

H. Cylinder connection pipe

Figure 8-1.--A portable oxyacetylene outfit.

D.

Header pipe

J. Check valve and drain plug

K. Acetylene cylinders

E.

Regulator

the open spaces in the cylinder and thus reduce the

Figure 8-2.--Stationary acetylene cylinder bank.

danger of explosion. At approximately 29 psi (pounds

per square inch), pure acetylene can be exploded by

nothing more than a slight shock; dissolved in acetone,

however, and stored in cylinders that are filled with

porous material, acetylene can be compressed safely

into cylinders at pressures up to 250 psi. An acetylene

cylinder is shown in figure 8-3. The acetylene cylinder

must be in the vertical position a minimum of 2 hours

before use to allow the porous filler material to settle

and to prevent it from being drawn into the hose,

gauges, and torch.

MAPP GAS

MAPP (methylacetylene-propadiene) gas is an all-

purpose industrial fuel that has the high flame tempera-

ture of acetylene and the handling characteristics of

propane. Being a liquid, MAPP gas is obtained by the

pound rather than by the cubic foot, as with acetylene.

One 70-pound (31.5-kg) cylinder of MAPP gas will do

the work of more than 6 1/2, 225-cubic foot acetylene

cylinders. This is a ratio of 70 pounds of MAPP gas to

1,500 cubic feet of acetylene.

The total weight for the 70-pound (31.5-kg)

MAPP cylinder, which is the same physical size as a

Figure 8-3.--Acetylene cylinder.

8-2