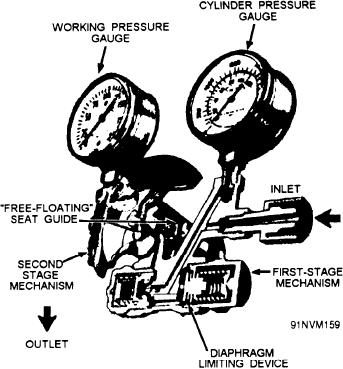

which the high-pressure gases pass, a valve seat to

close off the nozzle, a diaphragm, and balancing

springs. These are all enclosed in a suitable housing.

Pressure gauges are provided to indicate the pressure

in the cylinder or pipeline (inlet), as well as the

working pressure (outlet). The inlet pressure gauge,

used to record cylinder pressures, is a high-pressure

gauge; the outlet pressure gauge, used to record

working pressures, is a low-pressure gauge. Acetylene

regulators and oxygen regulators are of the same

general type, although those designed for acetylene are

not made to withstand such high pressures as are those

designed for use with oxygen cylinders.

In the regulator, the gas enters the regulator

through the high-pressure inlet connection and passes

through a glass wool filter that removes dust and dirt.

Turning the adjusting screw in, to the right, allows the

gas to pass from the high-pressure chamber to the

low-pressure chamber of the regulator, through the

regulator outlet, and through the hose to the torch.

Figure 8-5.--Two-stage regulator.

Turning the adjusting screw to the right INCREASES

the working pressure; turning it to the left

DECREASES the working pressure. The high-

a handle (body), two tubes (one for oxygen and one for

pressure gauge is graduated in pounds per square inch

acetylene), a mixing head, and a tip. Welding tips are

from 0 to 3,000 for oxygen and 0 to 400 for acetylene.

made from a special copper alloy, which dissipates

This permits reading of the gauge to determine

heat (less than 60 percent copper), and are available in

cylinder pressure. The gauges are graduated to read

correctly at 70F. The working pressure gauge is

different sizes to handle a wide range of plate

graduated in pounds per square inch from 0 to 30 for

thicknesses.

acetylene and from 0 to 50, 0 to 100, 0 to 200, or 0 to

There are two types of welding torches, the

400 for oxygen, depending upon the purpose for which

low-pressure type and the medium-pressure type. In

the regulator is designed. For example, on regulators

the low-pressure type, the acetylene pressure is 1 psi

designed for heavy cutting, the working pressure

or less. A jet of high-pressure oxygen is necessary to

gauge is graduated in pounds per square inch from 0

produce a suction effect, which draws in the required

to 400.

amount of acetylene. This is accomplished by the

The two-stage regulator is similar in principle to

design of the mixer in the torch, which operates on the

the one-stage regulator, the chief difference being that

injector principle. The welding tips may or may not

the total pressure drop takes place in two steps instead

have separate injectors designed into the tip. A typical

of one. In the high-pressure stage, the cylinder

mixing head for the low-pressure or injector type of

pressure is reduced to an intermediate pressure. In the

torch is shown in figure 8-6.

low-pressure stage, the pressure is reduced from the

intermediate pressure to a working pressure. A

In the medium-pressure torches, the acetylene is

two-stage regulator is shown in figure 8-5.

burned at pressures from 1 to 15 psi. These torches are

made to operate at equal pressures for acetylene and

WELDING TORCHES

oxygen. They are sometimes called equal-pressure or

balanced-pressure torches. The medium-pressure

The oxyacetylene welding torch is used to mix

torch is easier to adjust than the low-pressure torch

oxygen and acetylene gas in the proper proportions

and, because equal pressures are used, you are less

and to control the volume of these gases burned at the

likely to get a flashback. This means that the flame is

welding tip. Torches have two needle valves, one for

less likely to catch in or back of the mixing chamber.

adjusting the flow of oxygen and the other for

A typical equal-pressure torch is shown in figure 8-7.

adjusting the flow of acetylene. In addition, they have

8-4