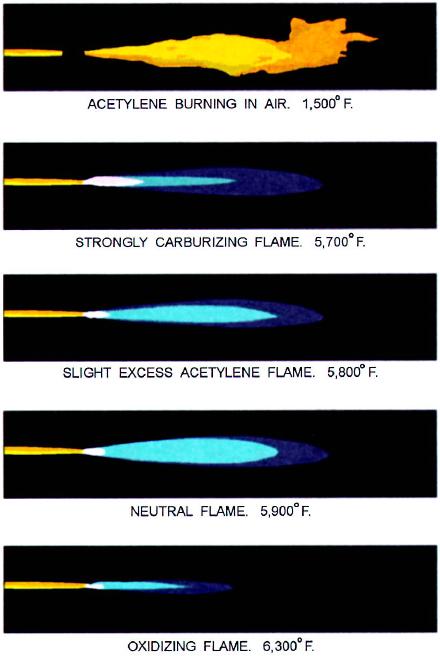

Figure 8-8.--Characteristics of the oxyacetylene flame.

flame. The carburizing flame bums with a temperature

of molten metal is quiet and clear, and the metal flows

without boiling, foaming, or sparking.

of about 5700F at the tip of the inner cone. When it is

used for welding steel, the metal boils and is not clear.

The REDUCING (or CARBURIZING) flame is

A carburizing flame is best for welding high-carbon

produced by burning an excess of acetylene. You will

steels, for hard-surfacing, and for welding nonferrous

be able to recognize it by the feather at the tip of the

alloys such as Monel.

inner cone. At the end of the inner cone, this feathery

The OXIDIZING flame is produced by burning an

tip has a greenish color. The degree of carburization

excess of oxygen. The oxidizing flame bums with a

can be judged from the length of the feather. For most

temperature of about 6300F at the tip of the inner

welding operations, the length of the feather should be

cone. You can identify this flame by the short outer

about twice the length of the inner cone. You can

flame and the small, white, inner cone. It takes about

always recognize the carburizing flame by its three

distinct colors. These are the bluish-white inner cone,

two parts of oxygen to one part of acetylene to produce

this flame, and you will find that the adjustment for the

a white intermediate cone, and the light-blue outer

8-8