specifications and standards, oxyacetylene cutting tips

are identified by three-part numbers. The first part is

the tip size (0, 1, 2, 3, and so on). The second part is

the drill size number of the orifice for the cutting

oxygen. The third part is the drill size number of the

preheat orifices. For example, the number l-62-64

identifies a number 1 tip with a cutting oxygen orifice

of drill size 62 and preheat orifices of drill size 64.

Table 8-1 gives tip numbers, orifice sizes, and

approximate cutting ranges of various sizes of oxya-

cetylene cutting tips. Cutting tips from different manu-

facturers are not interchangeable; when changing tips,

you must match the right tip with the right torch.

The tips and seats are designed and constructed to

produce a good flow of gases, to keep the tips as cool

as possible, and to produce leakproof joints. If the

joints leak, the preheat gases may mix with the cutting

oxygen or they may escape to the atmosphere.

It is very important that the orifices and passages

be kept clean and free of burrs to permit a free gas flow

and a well-shaped flame. Figure 8-12 shows four tips:

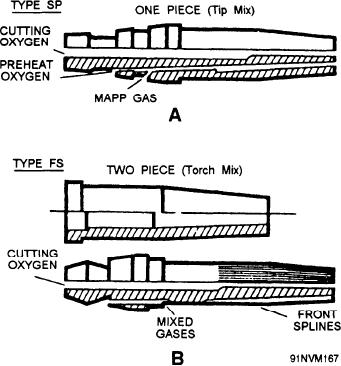

Figure 8-13.--MAPP gas cutting tips.

one that is repairable, two that need replacing, and one

in good condition. Since it is extremely important that

the sealing surfaces be kept clean and free of scratches

faster starts than the SP tips. However, two-piece tips

or burrs, the tips should be stored in a container that

will not take as much thermal abuse or physical abuse

cannot scratch the seats, preferably an aluminum or

as will one-piece tips. But in the hands of skilled

wood rack.

welders, they should last just as long as one-piece tips.

MAPP Gas Cutting Tips

Care of Tips

There are four basic types of MAPP gas cutting

In cutting operations, the stream of cutting oxygen

tips; two are designed for use with standard pressures

sometimes will blow slag and molten metal into the

and normal cutting speeds, and two for use with high

orifices and cause them to become partly clogged.

pressures and high cutting speeds. Only the standard

When this happens, you should clean the orifices

pressure tips, types SP (standard pressure) and FS (fine

thoroughly before you use the tip again; even a very

standard), will be covered here since they are the ones

small amount of slag or metal in an orifice will

that HTs will most likely use.

seriously interfere with the cutting operation. The

SP TIP.--The SP tip (fig. 8-13, view A) is a

recommendations of the torch manufacturer should be

one-piece standard-pressure tip. It is used for cutting

followed as to the size of drill or tip cleaner to use for

by hand, especially by welders who are accustomed to

cleaning the orifices. If you do not have a tip cleaner

one-piece tips. SP tips are also likely to be used in

or a drill, then you may use a piece of soft copper wire.

situations where MAPP gas is replacing acetylene as

Do not use twist drills, nails, or welding rods for

the fuel gas.

cleaning tips, as these items are likely to enlarge and

FS TIP.--The FS tip (fig. 8-13, view B) is a

distort the orifices.

two-piece, fine-spline, standard-pressure tip. It is used

The orifices of the cutting torch tip are cleaned in

for cutting by hand as well as by machine. Welders

the same manner as the single orifice of the welding

accustomed to two-piece cutting tips will use them in

torch tip. Remember that the proper technique for

hand cutting, especially in cases where MAPP gas is

cleaning the tips is to push the cleaner straight in and

replacing natural gas or propane as the fuel gas. The

FS tips will produce heavier preheating flames and

out of the orifice; be careful not to turn or twist it.

8-13