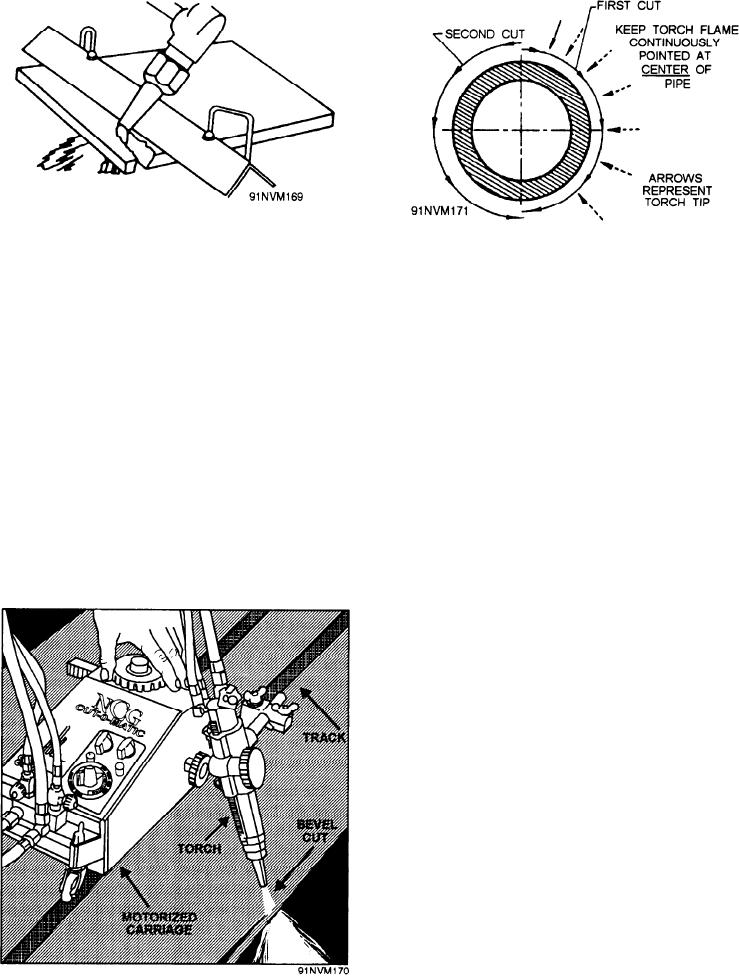

Figure 8-15.--Bevel cutting with an oxyacetylene torch.

Figure 8-17.--Cutting pipe with a cutting torch.

cut so you can tell how it is progressing. Make torch

Beveling Plate

adjustments if necessary. You must move the torch

along at the right speed. If you go too slowly, the

You will frequently have to cut bevels to form

preheating flame will melt the edges along the cut and

joints for welding. To make a bevel cut of 45 in 1-inch

may even weld them back together at the top surface.

steel, the flame must actually cut through 1.4 inches of

If you go too fast, the oxygen will not penetrate

metal. Consider this when selecting the tip size and gas

completely through the metal, and the cut will be

working pressures. You will have to use more pressure

incomplete. If you must restart or recut your work, do

and less speed for a bevel cut than for a straight cut.

so on the waste side of your metal. This serves three

When you are bevel cutting, adjust the tip so that the

purposes. First, it is easier to restart your cut on the

preheating orifices are lined up for efficient pre-

edge of the kerf than in the center. Second, you don't

heating. A piece of 1 -inch angle iron, clamped with the

leave an unsightly gouge or nick in your finished work

angle up, makes an excellent guide for beveling

where you restarted your cut. And finally, you don't

straight edges. Pull the torch along the guide as shown

cut your metal too short by recutting the edge.

in figure 8-15.

If you are aboard a repair ship or a tender, you may

have a radiograph automatic cutting machine similar

to the one in figure 8-16. This is a motor-driven cutting

machine designed to support the cutting torch and

guide it along the line of cut. It can be set to make

uniformly clean cuts or bevels on steel plate.

Straight-line cutting or beveling is done by guiding the

machine along a straight line on steel tracks. Arcs and

circles are cut by guiding the machine with a radius

rod pivoted about a center point.

Cutting and Beveling Pipe

When you are cutting off a piece of pipe, keep the

torch pointed toward the center line of the pipe. Start

the cut at the top and cut down one side. Then begin at

the top again and cut down the other side, finishing at

the bottom of the pipe. The procedure is shown in

figure 8-17.

Sometimes it is necessary to take T and Y fittings

from pipe. Here the cutting torch is a most valuable

Figure 8-16.--Bevel cutting on a circular path with a

radiograph automatic cutting machine.

tool. The usual procedure for fabricating pipe fittings

8-15