A low-velocity cutting tip has a cutting oxygen orifice

cutting torch to bring the head of the rivet up to the

proper temperature; then introduce the cutting oxygen

with a large diameter. Above this orifice are three

by gradually depressing the oxygen lever, and wash

heating orifices. Always place a low-velocity cutting

off the rivet head. The remaining portion of the rivet

tip in the torch so that the heating orifices are above

can then be punched out with a light hammer blow.

the cutting orifice when the torch is held in the rivet

The step-by-step procedure follows:

cutting position. To remove countersunk rivets from a

vertical sheet or plate, use the method shown in figure

1. Use the size of tip and the oxygen pressure

8-21 and follow these instructions:

required for the size and type of rivet you are going to

cut.

1. Hold the torch horizontally and turn it so that the

tip also points horizontally.

2. Heat a spot on the head until it is bright red.

2. Tilt the tip upward about 15 and hold the

3. Move the tip to a position parallel with the

preheating flames on a point slightly below the center

surface of the plate and slowly turn on the cutting

of the rivet head.

oxygen.

3. When you get the area heated to a dull red, move

4. Cut a slot in the rivet head like the screwdriver

slot in a roundhead screw. When the cut nears the plate,

the torch upward, still keeping the upward tilt, and press

draw the nozzle back at least 1 1/2 inches from the rivet

the cutting oxygen lever.

so that you will not cut through the plate.

4. Hold the torch steady with the cutting stream

5. When you have cut the slot through to the plate,

directed at the center of the rivet. As the rivet is cut away,

swing the tip through a small arc. This slices off half of

the angle of the torch should be decreased until the tip

the rivet head.

is perpendicular to the sheet or plate and the cutting

6. Then swing the tip in an arc in the other direction

stream is directed at the center of the rivet.

to slice off the other half of the rivet head.

5. When you have cut through the head to the shank

By the time the slot has been cut, the rest of the

of the rivet, wash away the remainder of the head with

rivet head has usually been heated to cutting

one circular wiping motion. Always move the torch so

temperature. Just before you get through the slot, draw

that the cutting stream will follow the preheat.

the torch tip back 1 1/2 inches to allow the cutting

6. The shank may then be removed by a light tap

oxygen to scatter slightly. This keeps the torch from

with a hammer and punch.

breaking through the layer of scale that is always

present between the rivet head and the plate. It allows

Buttonhead rivets may be removed in the same

the head of the rivet to be cut off without damaging the

manner as countersunk rivets with the low-velocity

surface of the plate. If you do not draw the tip away,

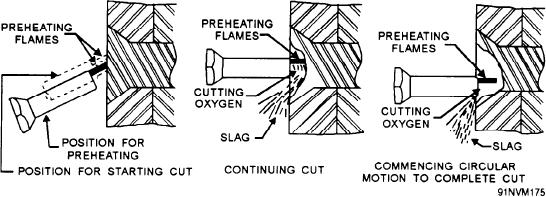

cutting tip. The process is illustrated step by step in

you may cut through the film of scale and into the plate.

figure 8-22. Remember that it is important to start

below the center of the rivet head so that molten metal

A low-velocity cutting tip is best for cutting

and slag will not be deposited on the plate.

buttonhead rivets and for removing countersunk rivets.

Figure 8-21.--Cutting a countersunk rivet with a low-velocity cutting tip.

8-18