The filler rod is kept ahead of the torch tip in the

direction in which the weld is being made. Point the

flame in the direction of the welding and hold the torch

tip at an angle of about 45 to 60 to the plates. (See fig.

8-26.) This position of the flame preheats the edges you

are welding just ahead of the molten puddle. By moving

the torch tip and filler rod back and forth in opposite,

semicircular paths, you balance the heat to melt the end

of the filler rod and the side walls of the joint into a

uniformly distributed molten puddle. As the flame

passes the filler rod, it melts off a short length of the

filler rod and adds it to the puddle. The motion of the

torch tip distributes the molten metal evenly to both

edges of the joint and to the molten puddle. This method

is used in all positions for welding sheets and light plates

up to one-eighth inch thick because it permits better

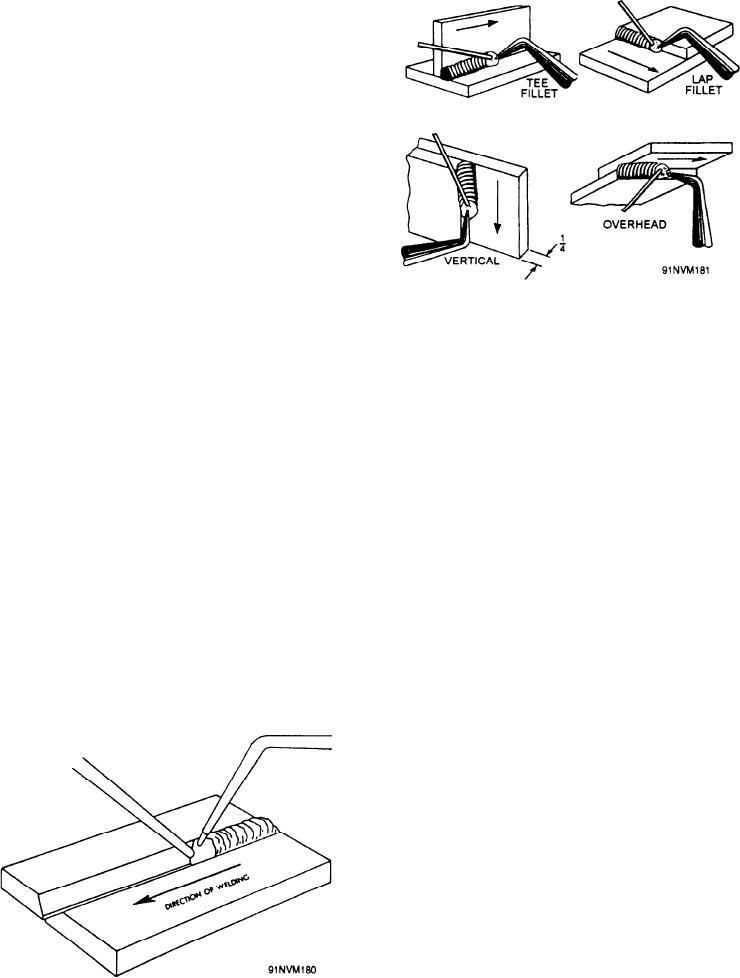

Figure 8-27.--Backhand welding.

control of a small puddle and results in a smoother weld.

The forehand technique is not the best method for weld-

ing heavy plate.

torch tip is moved back and forth across the weld while

BACKHAND WELDING is a newer method of

it is advanced slowly and uniformly in the direction of

welding. In this method, the torch tip precedes the filler

the welding. You'll find the backhand method best for

rod in the direction of welding, and the flame is pointed

welding material more than one-eighth inch thick. You

back at the molten puddle and the completed weld. The

can use a narrower V at the joint than is possible in

end of the filler rod is placed between the torch tip and

forehand welding. An included angle of 60 is a suffi-

the molten puddle, and the welding torch tip should

cient angle of bevel to get a good joint. It doesn't take

make an angle of about 45 to 60 with the plates or joint

as much filler rod or puddling for the backhand method

being welded. (See fig. 8-27.)

as it does for the forehand method.

Less motion is required in the backhand method

By using the backhand technique on heavier mate-

than in the forehand method. If you use a straight filler

rial, you can obtain increased welding speeds, better

rod, it should be rotated so that the end will roll from

control of the larger puddle, and more complete fusion

side to side and melt off evenly. You may also bend the

at the root of the weld. Further, by using a reducing

filler rod and, when welding, move the filler rod and

flame with the backhand technique, a smaller amount of

torch tip back and forth at a rather rapid rate. If you are

base metal is melted while welding the joint. When

making a large weld, you should move the filler rod so

welding steel with a backhand technique and a reducing

as to make complete circles in the molten puddle. The

flame, the absorption of carbon by a thin surface layer

of metal reduces the melting point of the steel. This

speeds up the welding operation.

MULTILAYER WELDING is used in welding

thick plate and pipe to avoid carrying too large a

puddle of molten metal, which is difficult to control.

Concentrate on getting a good weld at the bottom of

the V in the first pass. Then in the next layers,

concentrate on getting good fusion with the sides of

the V and the previous layer. The final layer is easily

controlled to get a smooth surface. This method of

welding has an added advantage in that it refines one

layer as the succeeding layer is made. In effect, it heat

treats the weld metal by allowing one layer to cool to

a black heat before it is reheated. This improves the

ductility of the weld metal. If this added quality is

desired in the last layer, an additional or succeeding

layer is deposited and then machined off.

Figure 8-26.--Forehand welding.

8-22