the selection of the proper welding rod. Low-alloy

Making a Joint

steels usually require preheating and postheating.

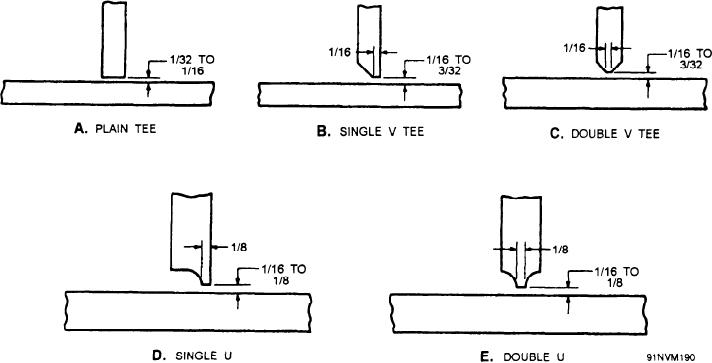

The T joint is another simple joint that is formed

As the carbon content increases, steels become

by butting the edge of a piece of plate up to the face of

more difficult to weld. Steels with a carbon content of

another plate to form the letter T. A plain T joint in thin

0.30 to 0.50 percent should be welded with a slightly

material requires little preparation. For thicker plate,

reducing (carburizing) flame, and should be

the edges should be prepared as shown in figure 8-36.

postheated to develop the best physical properties and

to reduce internal stress.

GUIDE FOR OXYACETYLENE WELDING

High-carbon steels and tool steels require

OF FERROUS METALS

somewhat special techniques if they are to be

successfully welded. Slow preheating to about 1000F

Low-carbon steel, low-alloy steel, cast steel, and

is required; the metal should be protected from drafts

wrought iron are easily welded by the oxyacetylene

during the preheating. No flux is required. The welding

process. A flux is not necessary with these materials,

should be completed as rapidly as possible with a

since the oxides melt at a lower temperature than the

carburizing flame. The filler rod and the torch tip

base metal. You must keep the molten puddle of metal

should not be manipulated for the welding of

enclosed by an envelope of flame at all times during

high-carbon steels and tool steels. Filler metal should

the welding process. If the metal is permitted to come

be added in small amounts, just as it is needed. A

in contact with the air while it is in a molten condition,

smaller flame and a lower gas pressure should be used

it will oxidize rapidly. Care should be taken to prevent

for these materials than for low-carbon steel since

overheating the metal. Use a neutral or slightly

there is even more danger of overheating the

reducing (carburizing) flame. Do NOT use an

high-carbon steels and the tool steels. High-carbon

oxidizing flame. Manipulate the torch and the filler rod

steels and tool steels must be heat treated after

so that the top of the oxyacetylene cone is about

welding.

one-sixteenth to one-eighth inch from the surface of

the metal. Melt the end of the filler rod in the puddle,

The procedure for oxyacetylene welding of

wrought iron is the same as for low-carbon steel.

not with the flame. The welding of low-carbon steels

However, certain special considerations should be

and cast steels presents no special problems other than

Figure 8-36.--Edge preparation required for various types of T joints.

8-26